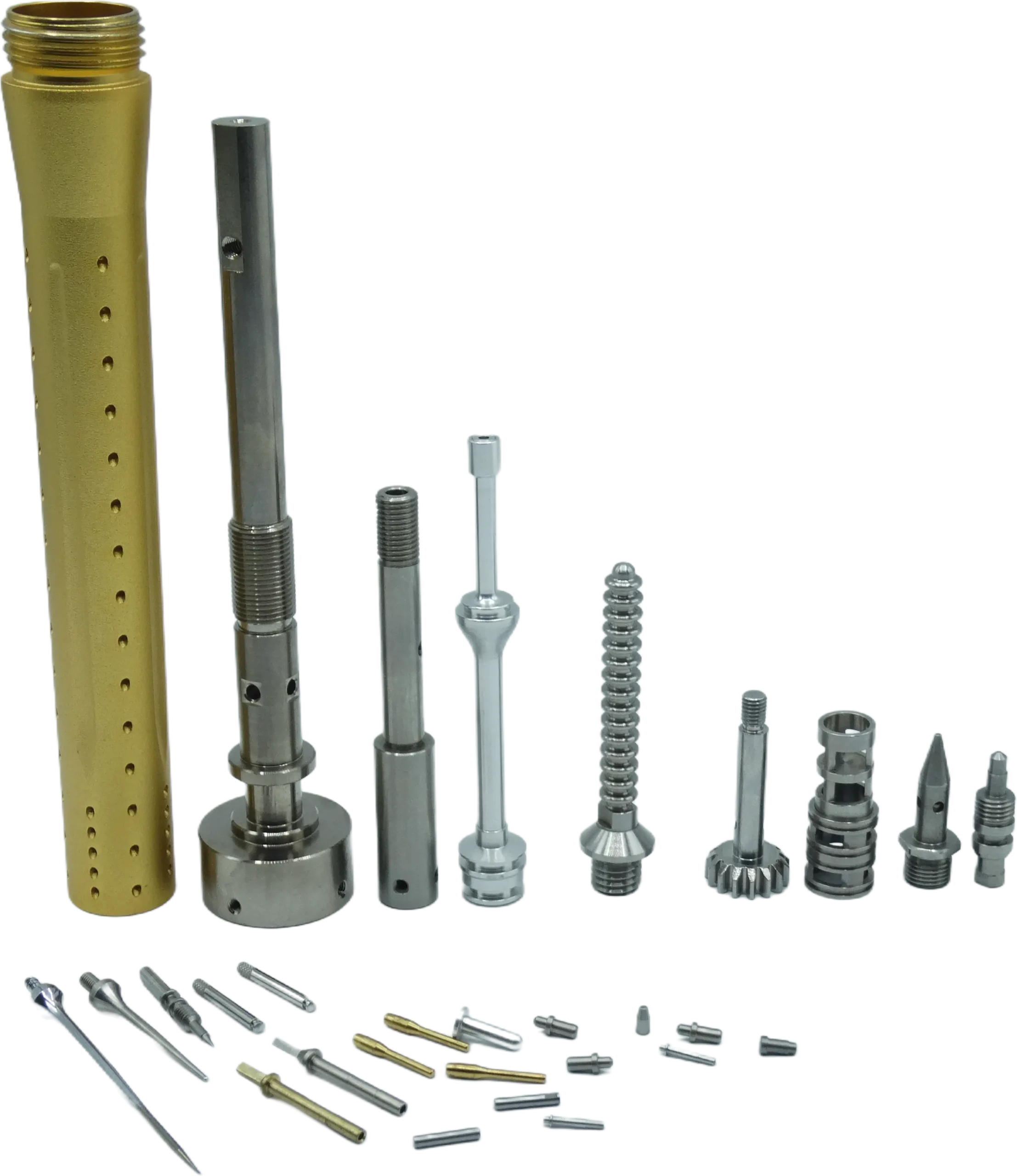

High-Precision Swiss CNC Machining Services

With 20+ years of expertise, JXD-Machining delivers custom precision parts to elevate your brand and boost profits.

•Diameter Range: 0.5mm–42mm

•Factory Pricing: Direct and cost-effective

•Precision: Tolerances up to ±0.0005

•Fast Turnaround: On-time delivery

(Save up to 40% on your projects!)

What is Swiss Machining?

——————

Swiss machining is a high-precision manufacturing technique that utilizes computer-controlled Swiss lathes to produce small and intricate components. Named after its origins in Switzerland, Swiss CNC lathes differ from conventional CNC machines by featuring multi-axis systems that allow simultaneous use of multiple cutting tools.

This technology is particularly well-suited for industries requiring tight tolerances and high precision, such as medical devices, aerospace, and electronics. Its capability to produce complex parts with exceptional efficiency makes Swiss machining an indispensable tool in modern manufacturing.

Key Benefits of Swiss Machining

Exceptional Tolerance Accuracy

Swiss machining delivers unparalleled precision, ensuring parts meet exact specifications and reducing the risk of assembly errors or product defects.

Superior Surface Finishes

The process produces outstanding surface smoothness, which is critical for industries where appearance and low friction are essential, enhancing the overall product quality and competitiveness.

Capability for Complex Parts

Swiss CNC machines excel at crafting intricate designs and geometries, enabling innovative product development without manufacturing constraints.

Fast Production Times

With short setup times and high-speed operations, Swiss machining ensures faster lead times, helping customers bring their products to market quickly.

Consistent Quality

Swiss machining is renowned for its consistency and repeatability, delivering high-quality parts with minimal variation, even in large production runs.

Reduced Material Waste

The process minimizes material waste, lowering production costs and supporting environmentally sustainable manufacturing practices.

Scalability

Whether it’s small-batch prototyping or large-scale production, Swiss machining offers the flexibility to meet varied manufacturing needs.

Integrated Secondary Operations

Swiss CNC machines can perform additional operations, such as drilling, tapping, and milling, in a single setup. This integration reduces costs and shortens delivery times.

Swiss Machining Applications: Precision Crafted for Every Industry

Swiss-Type Turning vs. Traditional CNC Turning

| Comparison Aspect | Swiss-Type Turning Center | Traditional CNC Turning |

|---|---|---|

| Precision and Accuracy | High precision, tight tolerances. | Good precision, adequate tolerances. |

| Complexity | Suitable for complex parts. | Better for simpler parts. |

| Material Waste | Reduced waste. | May generate more waste. |

| Setup Time | Faster setup time. | Longer setup time. |

| Tools | Uses multiple tools simultaneously. | Single-tool operation. |

| Workpiece Size | Limited to smaller diameters. | Handles larger diameters. |

| Part Holding | Guide bushing support. | Chuck holding. |

| Secondary Operations | Integrated operations. | Additional setups/machines required. |

Why Choose Our Swiss Machining Services?

Cost Efficiency

At AT-Machining, we prioritize quality while optimizing costs. Using advanced equipment and lean production methods, we help clients save 40%-60% on production costs without compromising reliability.

Strict Tolerance Control

Our expertise in Swiss machining ensures the production of components that meet stringent tolerance requirements. Advanced equipment, skilled engineers, and rigorous quality control guarantee consistent excellence.

Fast Turnaround Times

We understand the importance of on-time delivery. Our streamlined processes enable shorter lead times, with flexibility for quick modifications when needed.

Certified Quality Standards

JXD-Machining is ISO 9001:2015 certified, demonstrating our commitment to delivering products that meet international quality standards. With robust quality management systems in place, we ensure every component is inspected and tested to meet your exact requirements.

FAQs

1. What is Swiss CNC machining, and how does it differ from traditional CNC machining?

Swiss CNC machining is a precision manufacturing method using Swiss-style lathes, designed for small, intricate parts with tight tolerances. Unlike traditional CNC machining, Swiss machining supports the workpiece with a guide bushing, allowing for higher accuracy, faster production, and less material waste.

2. What are the tolerances and precision levels achievable with Swiss machining?

Swiss CNC machining can achieve tolerances as tight as ±0.001mm, making it ideal for components with high precision requirements. Our advanced machines and skilled operators ensure consistency across large production volumes.

3. What is the typical production volume for Swiss machining?

Swiss CNC machining is flexible for both small-batch prototypes and large-scale production. Whether you need a few custom parts or thousands of high-precision components, we can tailor our services to your needs.

4. How long does it take to produce my parts?

Lead times depend on the complexity of your design, material availability, and production volume. In general:

• Prototype orders: 1–3 days

• Large production orders: 7–14 days

For urgent requirements, we also offer expedited services.

5.What quality certifications do you have?

We adhere to international quality standards and hold certifications such as ISO 9001 and AS9100. Our strict quality control process ensures every part meets your specifications.

6.Why should I choose your Swiss CNC machining services?

We offer:

• Cost Efficiency: Save 40–60% on manufacturing costs.

• Quick Turnaround: Rapid delivery with flexible scheduling.

• 24/7 Engineering Support: Dedicated assistance for your projects.

• Strict Quality Control: Guaranteed precision and reliability for every part.