One-Stop Injection Molding Solutions

· 30+ Surface finishes, 60+ Materials for you choose

· Insert molding, Overmold services are available

· NDA Agreement, Document Confidentiality

· Quick DFM Feedback

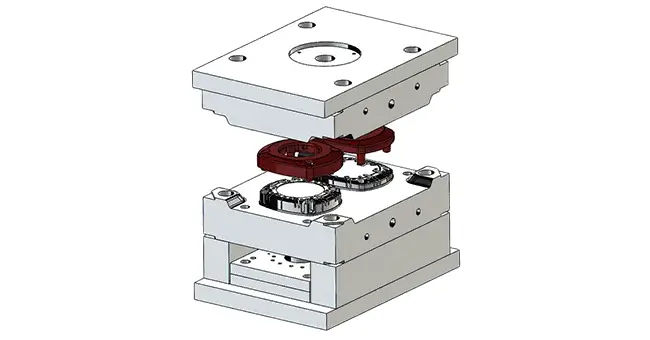

Injection Mold Solutions by JXD Manfuacturing

JXD specializes in precision injection molds, utilizing advanced CAD/CAM software and CNC machines. We also provide comprehensive mold repair and maintenance services to ensure exceptional quality and performance.

Prototyping & Small Batch Production

We specialize in rapid prototyping and low-volume injection molding, providing flexible and efficient solutions tailored to your needs.

• Single-cavity molds for precision parts

• Insert molds and MUD tooling options available

• Typical shot lifespan: 5K to 15K cycles

• Perfect for small-batch production and design validation

Mass Production & High-Performance Tools

Our production tooling is designed for durability and efficiency, ensuring reliable performance for high-volume manufacturing.

• Multi-cavity molds for maximum output efficiency

• High-quality steel tooling with advanced surface treatments

• Typical shot lifespan: 100K to 1.5M+ cycles

• Optimized for large-scale production across diverse industries

Injection Molding Capabilites

| Manufacturing Standards | Description |

|---|---|

| Maximum Part Size | 1200 × 800 × 400 mm |

| Minimum Part Size | 2 × 2 × 2 mm |

| Mold Cavities | Single - cavity molds, Multi - cavity molds, Family molds |

| Mold Tolerances | ± 0.02 mm |

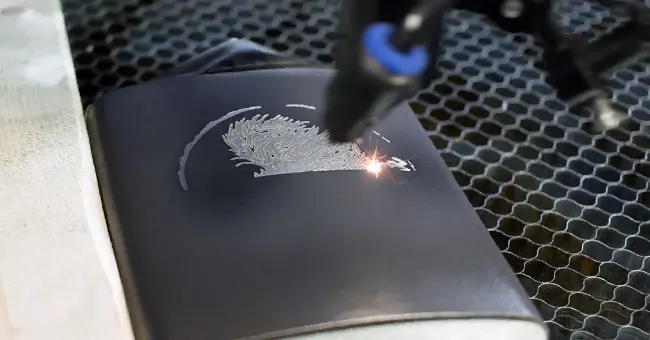

| Secondary Operations | Mold texturing, Pad printing, Silk screening, Laser engraving, Threaded inserts, Ultrasonic welding, Basic assembly |

| Undercuts | Y - type, L - type undercuts |

| Wall Thickness | 0.3 mm to 6 mm |

| Draft | 0.5° to 3° |

| Ribs/Gussets | 0.3 mm to 5 mm thick |

| Bosses | Diameter 2 mm to 20 mm |

| Materials Supported | ABS, PC, POM, Nylon, PP, PE, TPU, PA6/PA66, and customized engineering plastics |

| Surface Finishing Options | Polishing, Painting, UV Coating, Chrome Plating, Texture Coating, Sandblasting |

| Production Capacity | 50,000 to 1,000,000+ units per month |

| Lead Time | Mold fabrication: 10 - 20 days; Part production: 5 - 10 days |

| Certifications | ISO9001, Material certifications on request, Full dimensional inspection reports |

Our Injection Molding Workflow

1. Design Consultation

Collaborate with our engineering team to finalize product designs and select the most suitable materials for your project, ensuring optimal functionality and cost-efficiency.

2. Mold Development

We create precision molds using advanced CNC machining, ensuring dimensional accuracy and durability to meet your specific requirements.

3. Material Selection & Preparation

Support a wide range of materials, including engineering plastics. All raw materials undergo strict quality checks before production.

4. Injection Molding Process

Using state-of-the-art injection molding machines, we produce high-quality components with consistent precision, even for complex designs.

5. Secondary Operations

Enhance your parts with post-processing services such as polishing, texturing, silk screening, laser engraving, or assembly.

6. Quality Control & Delivery

Every batch undergoes rigorous inspections to ensure compliance with your specifications. Products are then carefully packed and shipped to your location.

Quality Control

Quality is at the core of everything we do. Our robust quality assurance process ensures your products meet the highest standards

1. ISO 9001 Certified Processes

Our production and quality control processes adhere to ISO 9001 standards, ensuring consistent quality and reliability in every product.

2. Inspection Reports

• Standard Inspection Reports: Included with every order to provide transparency on dimensions and specifications.

• Full Dimensional Inspection Reports: Available upon request for detailed verification.

3. Material Certifications

• Raw Material Certificates: Ensuring material authenticity and compliance with industry standards.

• Test Reports: Mechanical and chemical property test results are available on request to guarantee material performance.

4. In-Process Quality Checks

• Real-time monitoring during production to ensure dimensional accuracy and defect-free output.

• Advanced tools like CMM (Coordinate Measuring Machine) and laser scanners are used for precision verification.

5. Final Inspection

• Comprehensive quality checks covering dimensions, tolerances, surface finishes, and assembly compatibility.

• Only defect-free products are packed and shipped.

6. Traceability

• Each batch is fully traceable from raw materials to finished parts, ensuring accountability and quality consistency.

FAQ

1. What is the minimum order quantity (MOQ) for injection molding services?

Our MOQ starts as low as 1 piece, making it ideal for prototypes and small-batch production.

2. What materials do you work with for injection molding?

We work with a wide range of thermoplastics, including ABS, PC, Nylon, PP, POM, and custom materials based on your requirements.

3. Can you help with mold design and manufacturing?

Yes, we specialize in precision mold making using advanced CNC technology to ensure tight tolerances and high-quality results.

4. What is your typical lead time?

Lead times vary depending on project complexity, but we offer rapid prototyping with a lead time as short as 3 days.

5. Do you provide surface finishing options?

Absolutely. Our services include polishing, anodizing, powder coating, painting, and custom surface treatments to enhance part aesthetics and functionality.

6. Are you ISO-certified?

Yes, we adhere to ISO 9001 and, where applicable, ISO 13485 standards to ensure quality and reliability.

7. How do you ensure product quality?

We perform comprehensive quality checks at every stage of the process, from mold testing to final inspection, ensuring defect-free parts.

Contact Us for Tailored Injection Molding Solutions

Ready to bring your ideas to life? Let us help you with precision injection molding solutions.

Precision. Speed. Reliability – Your Partner in Injection Molding Solutions