Surface Finishing Services

Enhance the performance and appearance of your components with expert surface treatments, including sandblasting, anodizing, and powder coating, tailored to your needs.

• High-quality finishes for metal and plastic components.

• Fast turnaround, as quick as 7 days.

• Customized solutions for diverse applications.

• Reliable global shipping.

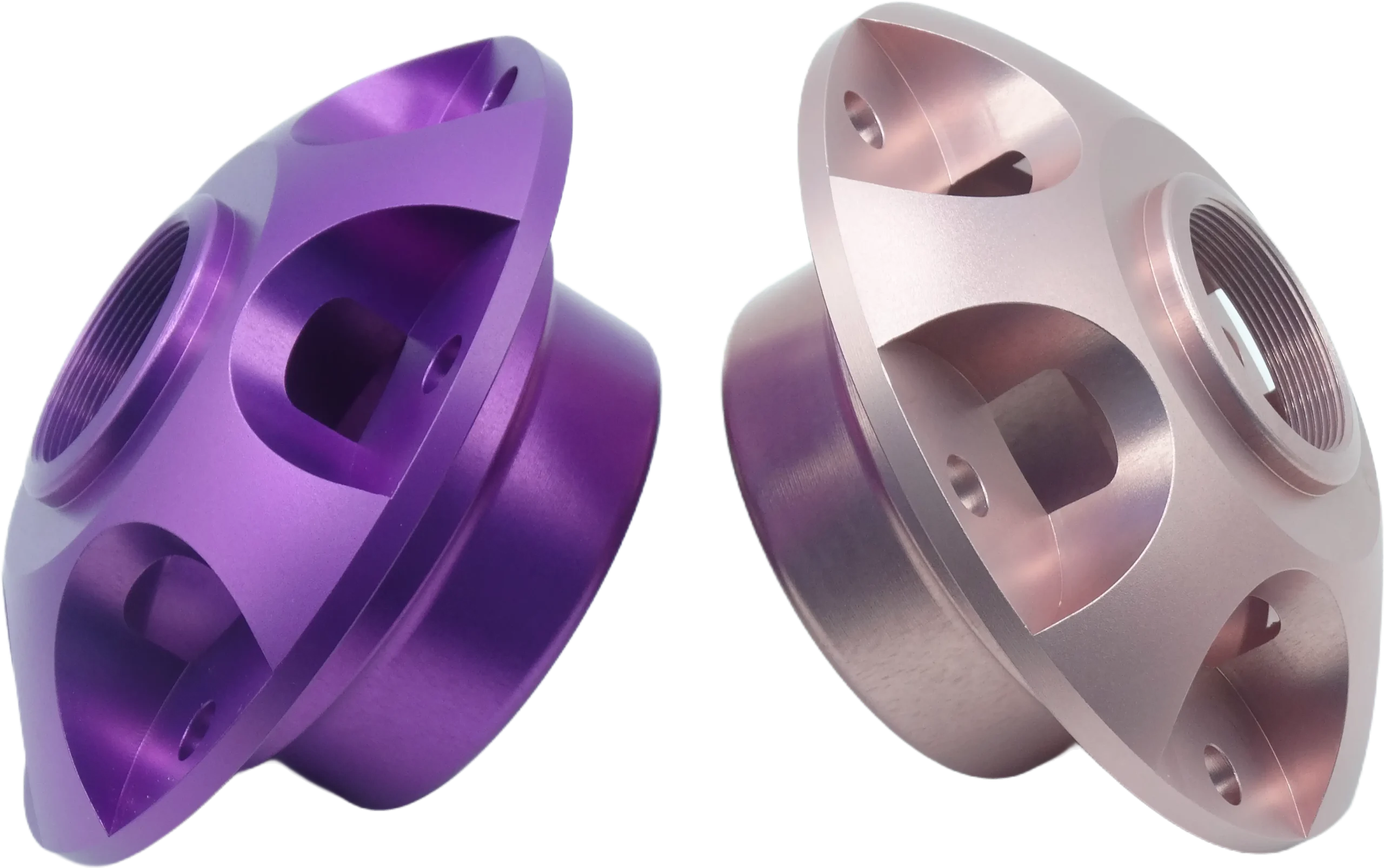

1. Anodizing

A process designed to enhance aluminum parts with improved corrosion resistance, durability, and decorative finishes. Ideal for industries like aerospace, electronics, and automotive.

| Feature | Details |

|---|---|

| Applicable Materials | Aluminum, aluminum alloys |

| Key Advantages | Corrosion resistance, wear resistance, aesthetic versatility |

| Industries Served | Aerospace, automotive, consumer electronics |

| Common Colors | Silver, black, gold, red |

| Surface Roughness (Ra) | 0.4-1.6 µm |

| Processing Time | Typically completed within 1-3 days |

2. Electroplating

Enhance the surface properties of metal parts with electroplating, offering excellent wear resistance, conductivity, and aesthetic appeal.

| Feature | Details |

|---|---|

| Applicable Materials | Steel, stainless steel, copper, zinc, and more |

| Key Advantages | Enhanced conductivity, corrosion protection, improved appearance |

| Industries Served | Hardware, electronics, mechanical components |

| Common Coatings | Nickel, chrome, gold, zinc |

| Surface Roughness (Ra) | 0.8-1.6 µm |

| Processing Time | Standard process takes 2-5 days |

3. Heat Treatment

Modify material properties like hardness, strength, and wear resistance through precise heat treatment techniques. Perfect for parts subjected to extreme stress.

| Feature | Details |

|---|---|

| Applicable Materials | Steel, aluminum alloys, titanium |

| Key Advantages | Improved hardness, enhanced strength, better toughness |

| Industries Served | Tools, machinery components, construction |

| Common Methods | Quenching, tempering, annealing, normalizing |

| Applicable Thickness | Ideal for parts 5-50 mm thick |

| Processing Time | Depends on complexity, typically 3-7 days |

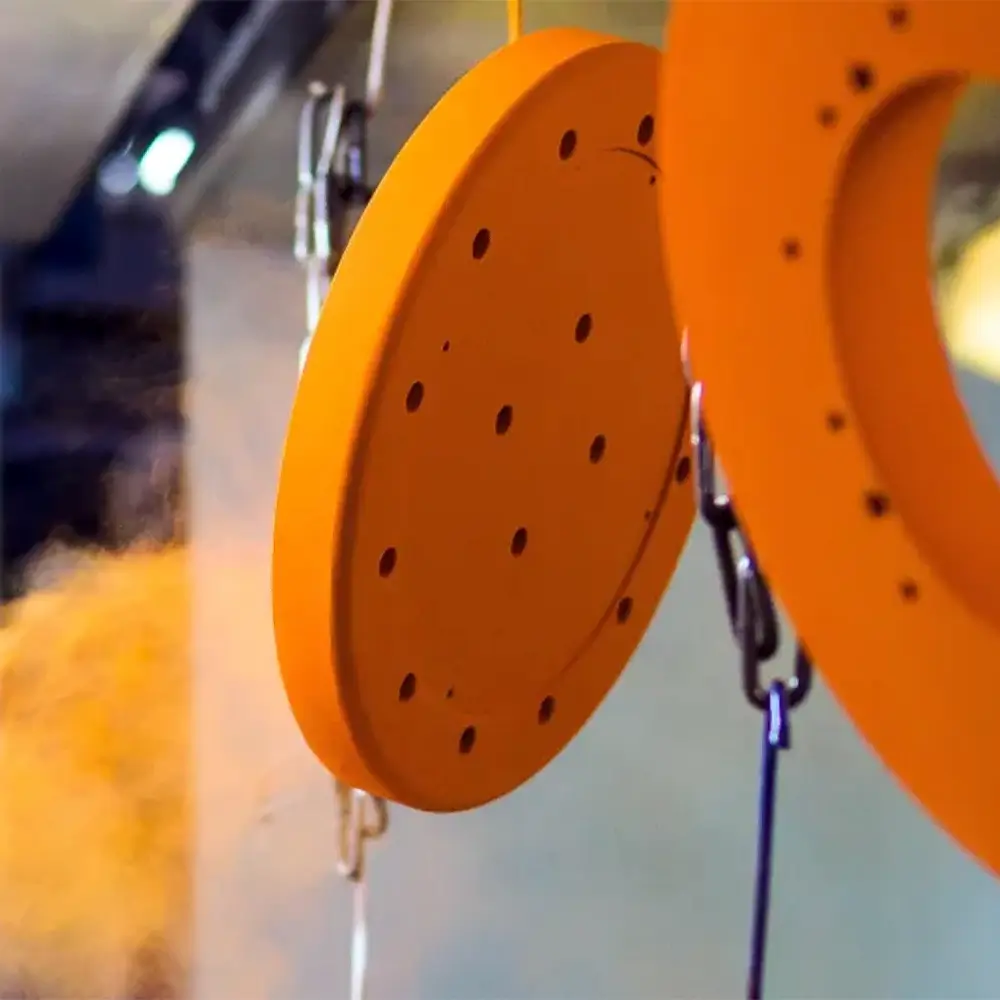

4. Powder Coating

A sustainable and vibrant surface finishing option that provides excellent protection against scratches, corrosion, and UV damage.

| Feature | Details |

|---|---|

| Applicable Materials | Steel, stainless steel, aluminum |

| Key Advantages | Eco-friendly, vibrant finishes, superior wear resistance |

| Industries Served | Furniture, appliances, industrial equipment |

| Common Applications | Frames, panels, housings |

| Surface Roughness (Ra) | 2.0-5.0 µm |

| Processing Time | Completed within 3-7 days |

5.Black Oxide

A reliable and cost-effective method for providing a sleek black finish and mild corrosion resistance without altering dimensions.

| Feature | Details |

|---|---|

| Applicable Materials | Steel, stainless steel, iron |

| Key Advantages | Anti-glare, corrosion resistance, improved aesthetics |

| Industries Served | Precision components, firearms, tools |

| Finish | Matte black |

| Processing Time | 2-5 days |

6. Polishing

Achieve a flawless, mirror-like surface or reduce roughness for improved functionality and aesthetics.

| Feature | Details |

|---|---|

| Applicable Materials | Metal, plastic |

| Key Advantages | Improved aesthetics, enhanced surface smoothness |

| Industries Served | Medical devices, optical components, decorative parts |

| Common Methods | Manual polishing, mechanical polishing |

| Surface Roughness (Ra) | Down to 0.1 µm |

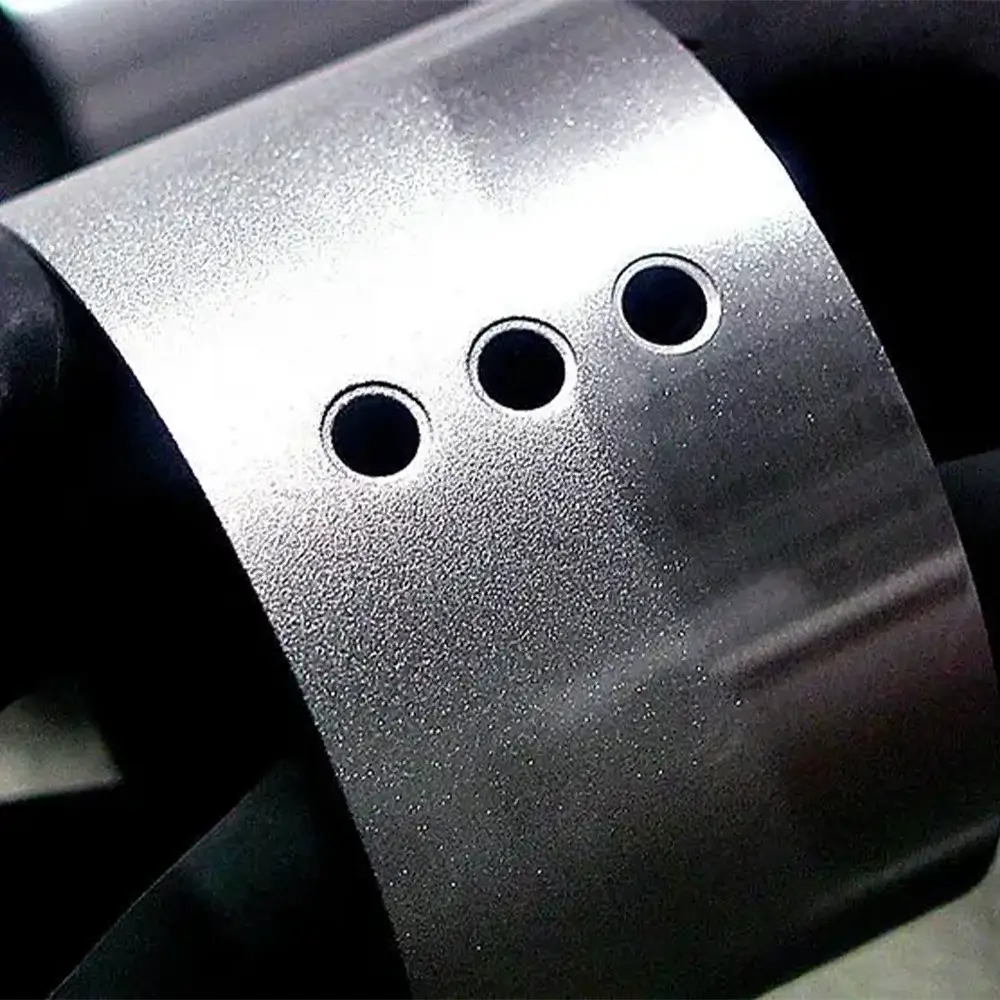

7. Sandblasting

Prepare or clean surfaces with precision, creating a uniform texture for subsequent treatments or aesthetic purposes.

| Feature | Details |

|---|---|

| Applicable Materials | Metal, wood, glass |

| Key Advantages | Surface cleaning, texturing, rust removal |

| Industries Served | Automotive, construction, restoration |

| Abrasive Types | Glass beads, aluminum oxide, silicon carbide |

| Processing Time | Varies by complexity, usually 1-3 days |

FAQ

1. What is the lead time for surface finishing services?

Lead times vary by process, but we can deliver within 7-10 days for most finishes.

2. Can I request custom colors for anodizing or powder coating?

Yes, we offer a wide range of colors, including custom shades.

3. What certifications do you provide for surface treatments?

We provide material certifications, inspection reports, and test data upon request.

4. What materials can you process?

We work with metals such as aluminum, stainless steel, and brass, as well as certain plastics.