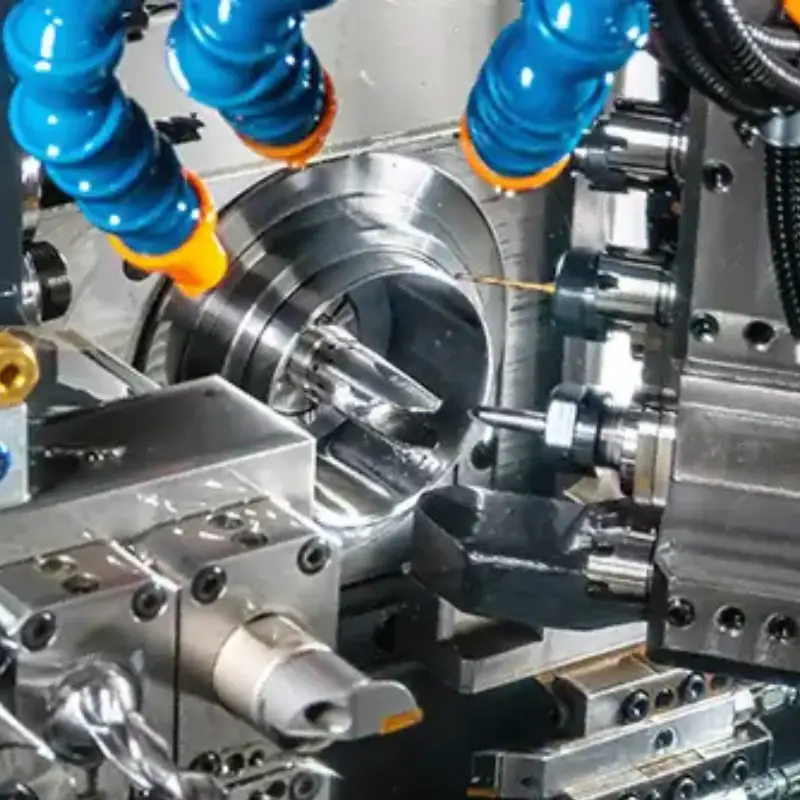

Metal CNC Machining

Partner with JXD for high-performance CNC metal machining. We combine cutting-edge technology and materials expertise to deliver parts that exceed expectations in accuracy, durability, and efficiency.

Metal Material

Aluminum

Lightweight yet strong, aluminum is the ideal choice for components requiring high strength-to-weight ratios. Its excellent machinability, corrosion resistance, and versatility make it perfect for industries like aerospace, automotive, and electronics

Titanium

Titanium’s unmatched strength and corrosion resistance make it indispensable in demanding industries such as aerospace, medical devices, and marine engineering. Its biocompatibility also ensures reliability in surgical applications.

Magnesium

Magnesium, as the lightest structural metal, combines high machinability with strength. It’s a favorite for applications requiring weight reduction, like automotive and aerospace parts, without compromising performance.

Copper

Copper stands out with its superior electrical and thermal conductivity. It’s the go-to material for electrical components, heat exchangers, and industrial applications where precision is key.

Stainless Steel

Stainless steel offers excellent corrosion resistance, durability, and a polished finish, making it suitable for medical instruments, food processing equipment, and architectural applications.

Steel

Steel provides high strength, wear resistance, and versatility, making it an industry-standard for heavy machinery, construction components, and custom tooling.

Brass

Brass offers a unique combination of corrosion resistance and aesthetic appeal. Commonly used for plumbing, electrical fittings, and decorative hardware, its ease of machining ensures efficiency in complex designs.

Bronze

Renowned for its robustness and ability to withstand harsh environments, bronze is widely used in marine hardware, bushings, and industrial bearings, offering longevity and reliability.

Our CNC Machining Services

Milling

Versatile and precise, milling produces intricate parts with tight tolerances, ideal for aerospace, automotive, and medical applications.

Turning

Perfect for cylindrical components, turning delivers smooth finishes and consistent precision for shafts, bushings, and fittings.

Swiss Machining

Ideal for small, complex parts, Swiss machining ensures exceptional accuracy, commonly used in medical, aerospace, and electronics industries.

EDM (Electrical Discharge Machining)

Specialized for intricate geometries and hard materials, EDM offers precise cuts and excellent surface quality for molds and tooling.

How to Choose the Right Material for Your Parts

Selecting the right material is a critical decision that affects your part’s performance, durability, and overall cost. Here’s a professional guide to help you navigate the process:

● Understand Your Project’s Needs

Consider the mechanical demands of your design. For heavy loads or high stress, metals like steel or titanium offer unmatched strength. If weight is a concern, aluminum or magnesium provides a lightweight yet durable alternative. For applications involving high temperatures, materials such as stainless steel or titanium are ideal.

● Evaluate Environmental Conditions

Take into account the environment where your part will operate. In corrosive settings, aluminum, stainless steel, or bronze resist rust and oxidation effectively. For components exposed to continuous friction, harder metals like steel or brass ensure greater wear resistance.

● Assess Machining Feasibility

Some metals, including aluminum and brass, are easier to machine, which lowers production costs and shortens lead times. Intricate designs may benefit from materials with excellent machinability to ensure precision in complex geometries.

● Balance Cost and Performance

Premium materials like titanium offer top-tier performance but may exceed budget constraints. For most applications, versatile options like aluminum or steel provide the best combination of affordability and functionality.

● Consult with Experts for Tailored Solutions

Every project has unique requirements. By working with experienced professionals, you can make informed decisions about materials that balance your needs for strength, durability, and cost-effectiveness.

FAQ

1.Can you provide material certifications for the metals used?

Yes, we can provide material certifications, such as mill test reports (MTRs), to ensure the quality and compliance of the materials we use.

2.What tolerances can you achieve with your CNC machining services?

Our standard tolerance is ±0.01 mm, but we can achieve tighter tolerances based on the material and machining process. Contact us with your specifications for more details.

3.Do you offer surface treatments for metal parts?

Yes, we provide a range of surface treatments, including anodizing, powder coating, plating, and polishing, to enhance appearance, durability, and corrosion resistance.

4.Are you able to machine custom alloys or specialized metals?

Yes, we can work with a variety of custom and specialized metals. Let us know your specific requirements, and we’ll assess the feasibility of your project.

5.How do you ensure the quality of machined metal parts?

We follow stringent quality control measures, including inspections during and after machining. Full dimensional inspection reports are available upon request.

6.Can you assist with design optimization for CNC machining?

Yes, our engineers can review your design and suggest optimizations to improve manufacturability, reduce costs, and enhance performance.