Drone detectors are essential devices widely used in areas such as security surveillance, search and rescue operations, and environmental monitoring. By capturing images, sensing temperature, or detecting motion, drone detectors play a pivotal role in ensuring that drones efficiently perform their tasks. Given the critical role these detectors play, their housing design and construction must balance precision, durability, and lightweight characteristics to protect the high-precision sensor systems housed within them.

The working principle of a drone detector depends on various sensors, such as infrared, radar, and optical sensors. These sensors collect and process environmental data during the drone’s flight, transmitting the information back to ground control stations. To ensure the detector operates reliably in harsh conditions, a robust housing is essential to shield the sensitive internal equipment, providing critical protection against environmental threats.

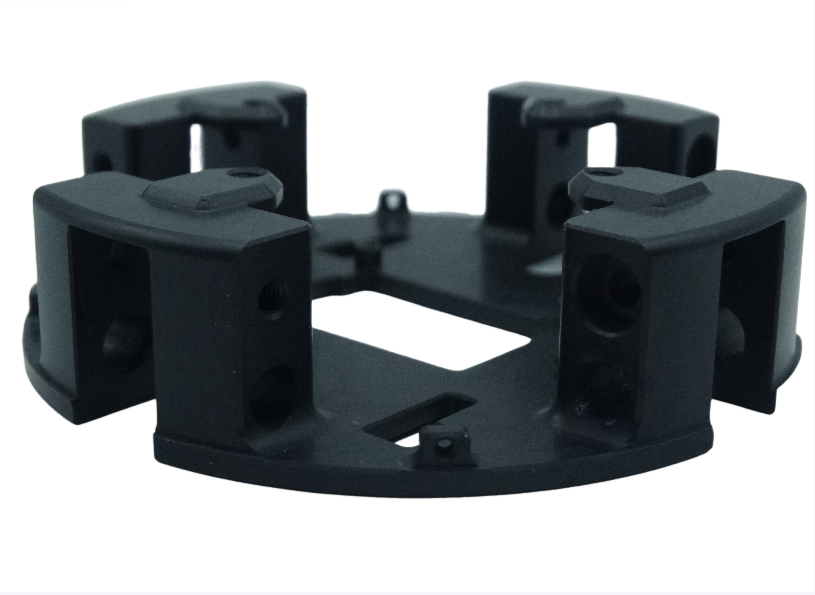

The housing of a drone detector is not merely a protective shell; it also includes multiple key components like brackets and seals. The housing is designed to protect against physical impacts, moisture, and electromagnetic interference, ensuring the detector remains stable and fully functional. The brackets secure the detector in place, preventing movement during flight due to vibrations or collisions, which is crucial for maintaining accurate data. The seals serve as barriers against dust, water, and heat, preventing the external environment from negatively affecting the detector’sperformance.

When it comes to the design and manufacturing of drone detector housings, several important requirements must be met. First, the housing must be lightweight to avoid adding excess weight to the drone, which could hinder flight performance. Second, it needs to be robust enough to withstand extreme environments, including strong winds, rain, and temperature fluctuations. Additionally, the manufacturing process must be precise to ensure the detector fits seamlessly and operates as intended. In some cases, the housing must also provide electromagnetic shielding to prevent external interference from affecting the internal systems.

At JXD, we have exceptional technical capabilities and extensive experience in producing high-quality drone detector housings. Our factory is equipped with the most advanced CNC machining equipment, capable of working with a variety of materials including aluminum, titanium, magnesium, and even 3D-printed components. We offer fully customizable solutions to meet the specific needs of our clients, ensuring high-precision metal parts that uphold the highest standards of quality and performance.

Our quality control system is rigorous, ensuring every step, from the initial design phase to final production, undergoes thorough inspection to guarantee that the housing meets the precise specifications provided by the client. Additionally, JXD offers customization services, including sample testing, ensuring that the products are fully tested before mass production begins. We also offer various surface treatments, such as anodizing, to enhance the housing’s corrosion resistance and durability, ensuring long-term operational stability.