Quality Assurance

Quality in Every Step, Trust in Every Part

1. Initial Preparations: Ensuring Quality from the Start

• Technical Evaluation:

Before production begins, our engineers thoroughly review your designs, including material selection, surface finish requirements, structural integrity, and 3D/2D drawings. This ensures both manufacturability and performance.

• Material Validation:

All raw materials are sourced from certified suppliers and come with detailed inspection reports, such as composition analysis and mechanical properties, ensuring reliability from the very beginning.

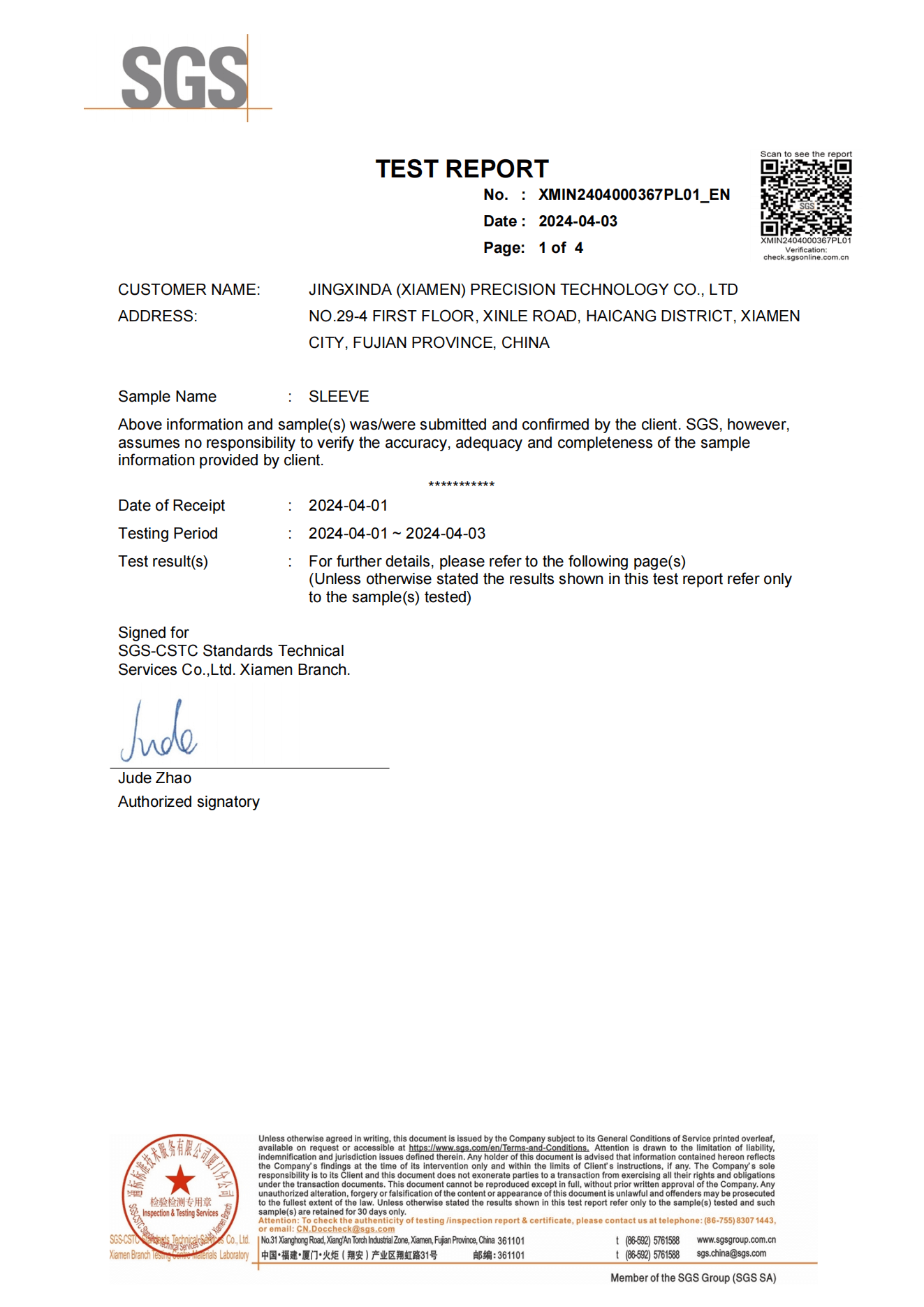

Quality Reports

JXD provides a Certificate of Conformance with every order, verifying that products are delivered according to the required specifications. This includes quality reports for plastic molding, stamping, forging, and CNC machining.

Material certificates validate the raw materials sourced by JXD, detailing their chemical composition and properties. These documents are supplied by trusted material vendors and ensure reliability for stamping, forging, CNC machining, and injection molding.

Dimensional reports verify the fundamental dimensions and tolerances of each part, based on random sampling from production batches. This ensures compliance with design specifications and accuracy in inspection.

RoHS reports certify that materials and finished components are free from restricted hazardous substances. These reports are applicable to CNC machining, injection molding, and other production processes, ensuring compliance with environmental regulations.

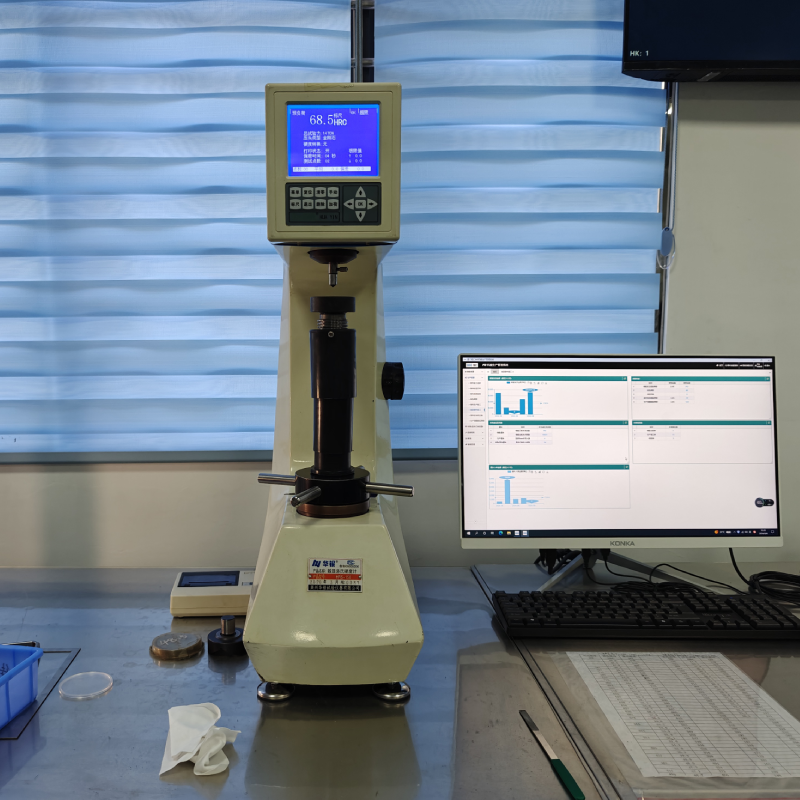

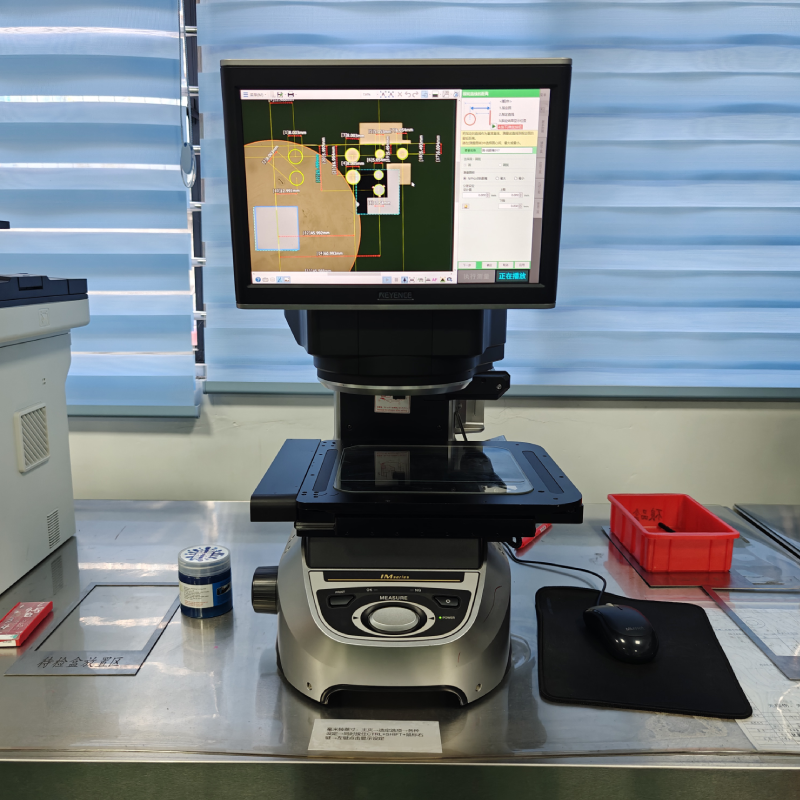

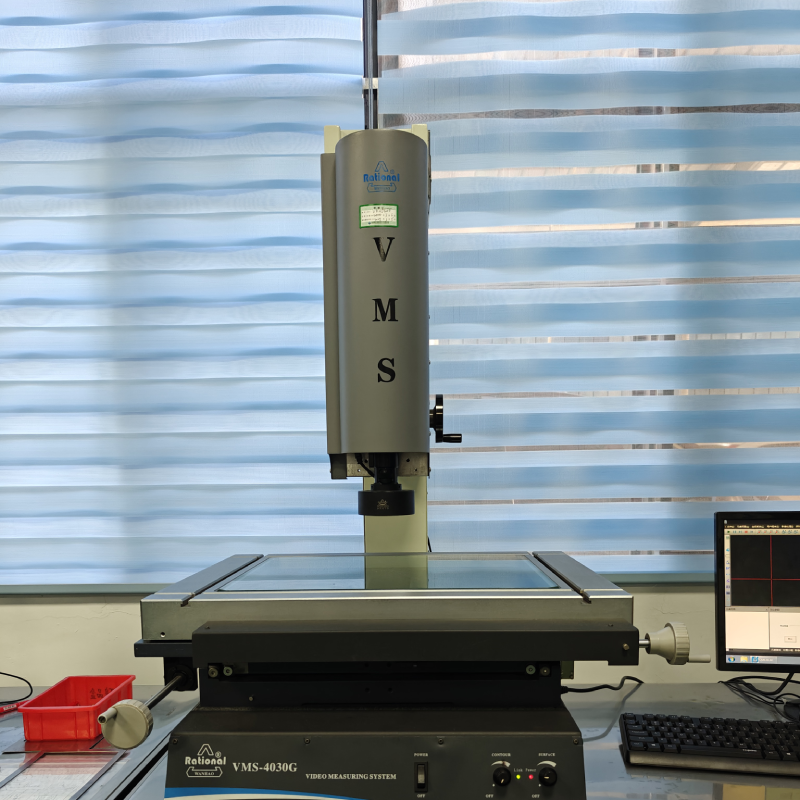

Inspection Equipment

At JXD, we invest in advanced inspection equipment to ensure every product meets the highest standards of precision and quality. From dimensional accuracy to material composition, our tools are designed to detect even the smallest deviations. Our state-of-the-art equipment includes:

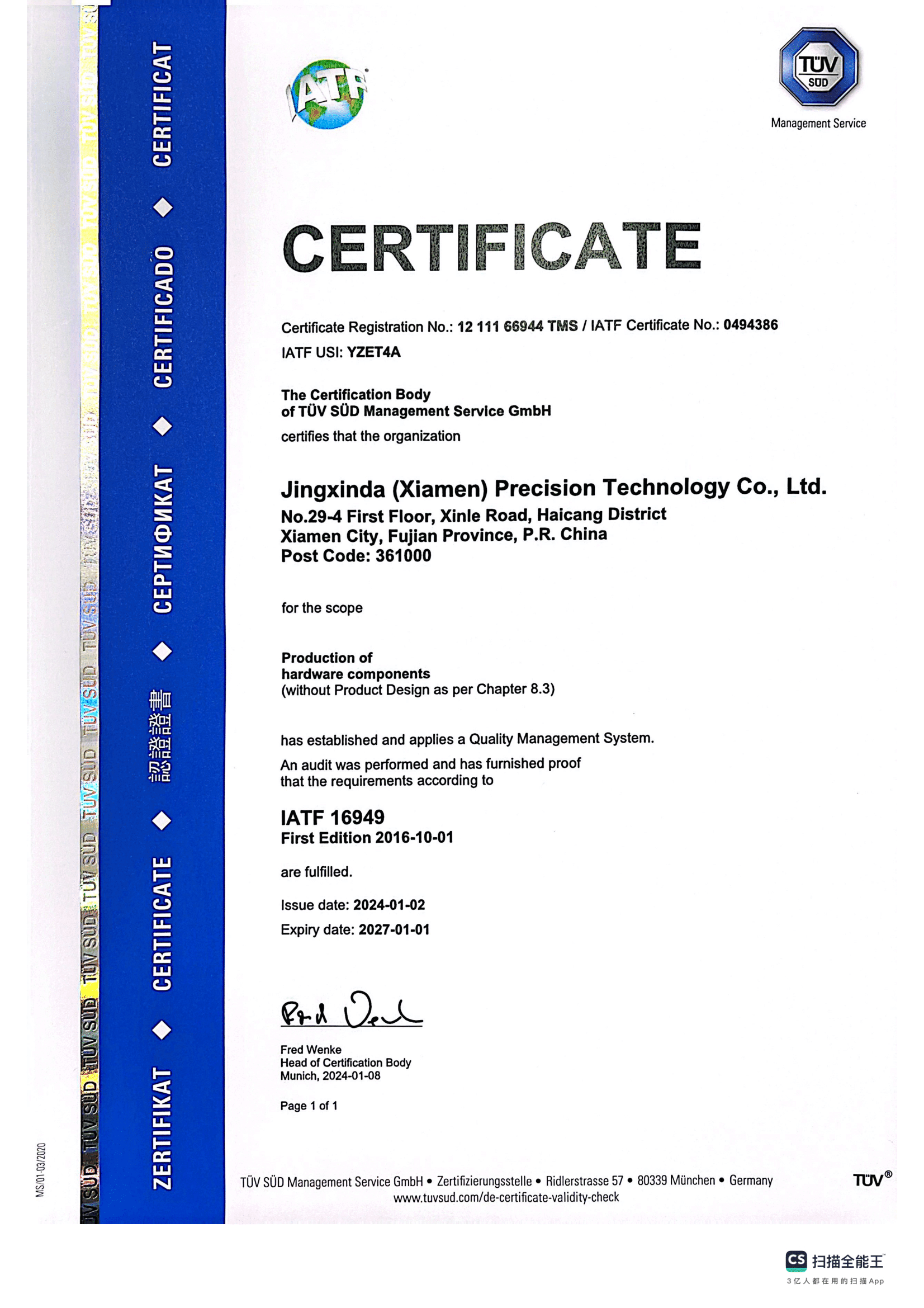

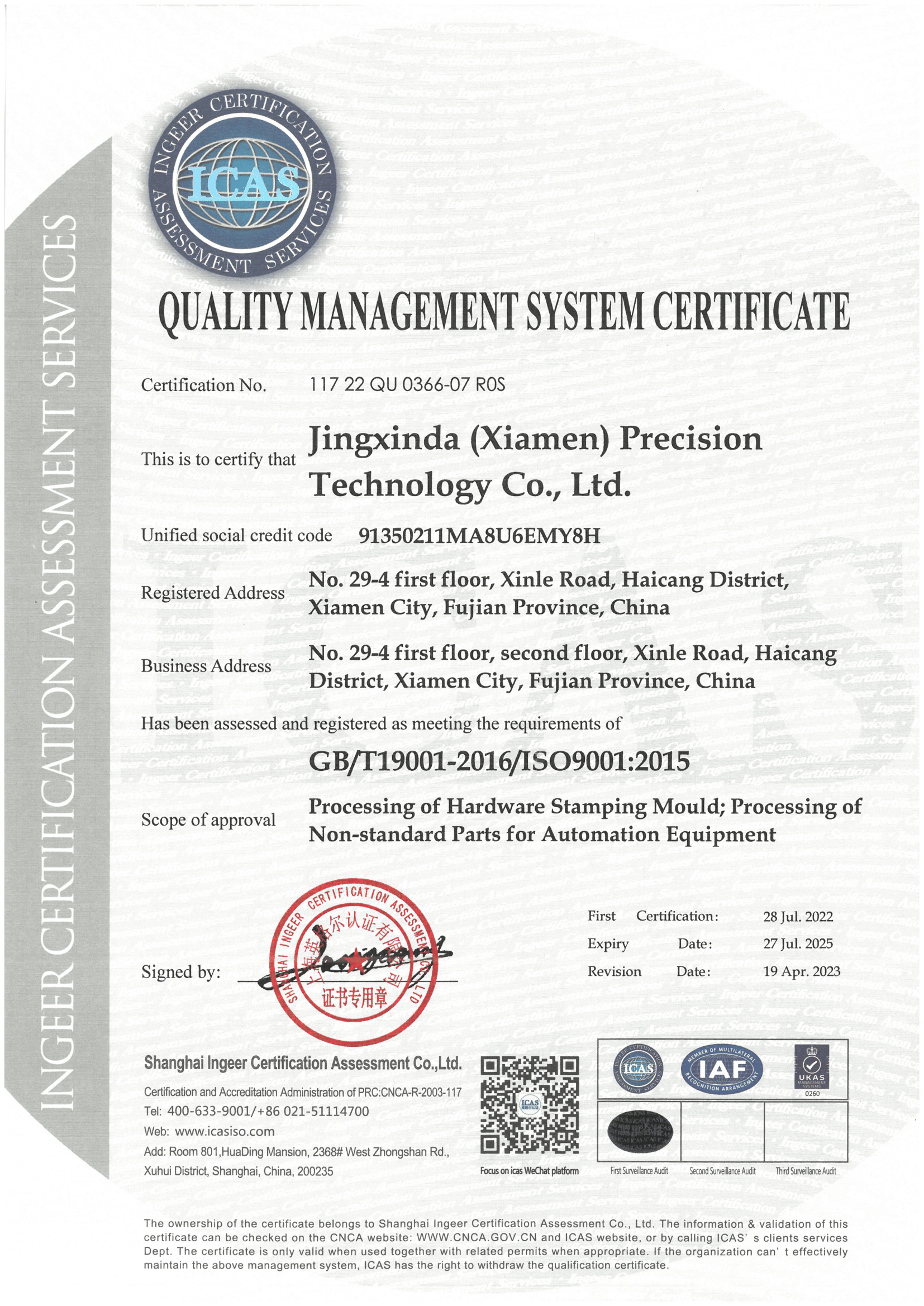

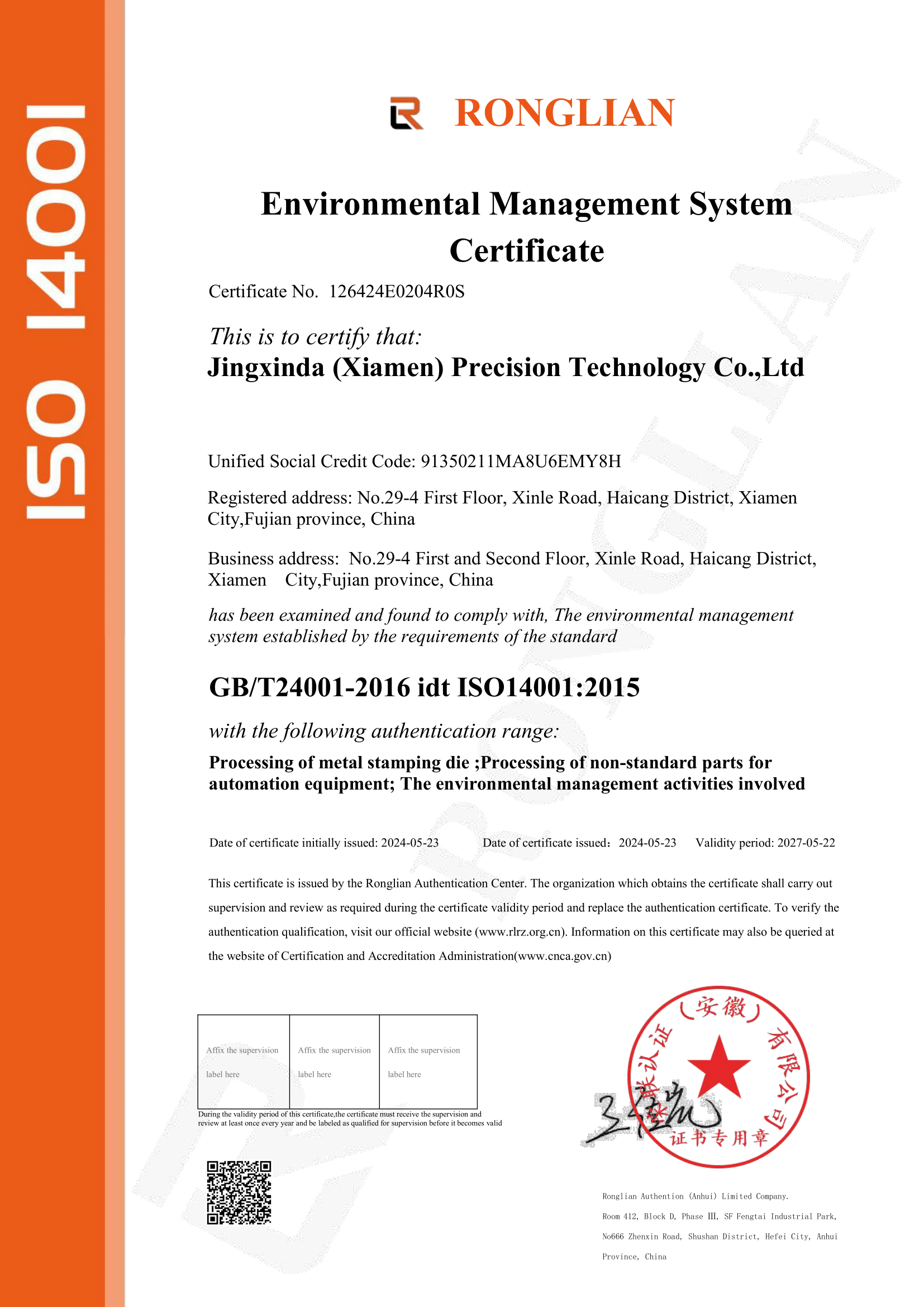

Certifications

JXD operates with a commitment to quality, backed by internationally recognized certifications. These certifications validate our dedication to compliance, safety, and excellence in every process: