Why Choose JXD for Custom Electronics Parts?

Our DFM process ensures your designs are optimized for efficient production, improving manufacturability and helping reduce production costs for custom electronic components.

At JXD, we adhere to stringent quality control procedures to ensure each custom electronic part meets the highest standards, providing designers and engineers with reliable, high-performance components they can trust.

We offer comprehensive technical support throughout the entire manufacturing process, assisting you in making well-informed decisions regarding your custom electronic parts.

JXD provides a wide range of customization options to meet the specific requirements and applications of your electronics projects, ensuring that each part is tailored to your exact needs.

With our rapid prototyping capabilities and efficient production processes, we help shorten time-to-market for your products, giving your business a competitive edge in the industry.

Electronic Applications

• Smartphones

Precision CNC parts for smartphones, designed for durability and compact integration.

• Laptops

Custom components for laptops, ensuring high performance and reliable functionality.

• Cameras

CNC-machined parts for cameras, including housing and internal components for optimal performance.

• Computer Accessories

Tailored parts for computer peripherals, offering durability and seamless functionality.

• Wireless Communication Devices

Components for wireless communication, crafted for reliability and signal clarity.

• Circuit Boards & PCBs

High-precision machining for circuit boards and PCBs, ensuring accuracy and perfect fit.

• Electronic Cases & Housing Parts

Custom enclosures and housing for sensitive electronic devices, providing protection and ease of assembly.

• Custom Fixturing

Custom fixturing solutions for electronic assembly and testing, designed for precision and repeatability.

• Enclosures

Durable enclosures for various electronics, providing safety and protection from environmental factors.

• Integrated Circuits

Precision parts for integrated circuits (ICs), crafted to ensure performance and reliability.

• Switches

High-quality switches, designed and machined to meet specific electronic performance needs.

• Circuit Breakers

Custom CNC components for circuit breakers, ensuring safety and optimal performance.

• Microcontrollers

Parts for microcontroller housings, ensuring protection and integration with other electronics.

• Engine Control Units

Precision-engineered parts for engine control units (ECUs), built for high-performance applications.

• GPS Navigation

Custom CNC components for GPS navigation systems, ensuring accuracy and reliability.

• Power Converters

Machined parts for power converters, designed for efficiency and longevity in energy conversion.

• Actuators

Precision parts for actuators, ensuring smooth operation in electronic systems.

• Motor Drives

Custom motor drive components, providing durability and performance in power systems.

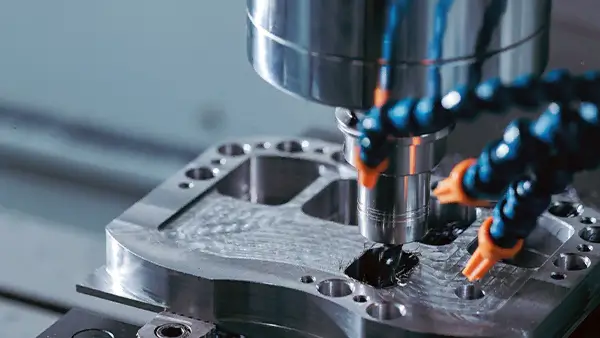

JXD Electronic Manufacturing Capabilities

CNC Milling Services

Accurately produce intricate geometries with our advanced CNC milling capabilities, ideal for aerospace, automotive, and electronics industries

CNC Turning Services

Efficiently manufacture cylindrical parts with tight tolerances and smooth finishes, perfect for shafts, bushings, and custom fittings.

Injection Molding

Create custom plastic parts with precision injection molding, suitable for both low- and large-scale production needs.

Sheet Metal Fabrication

Fabricate high-quality sheet metal parts with precise cutting, bending, and assembly for versatile applications.

FAQ

Q: What types of electronic parts can JXD Machining manufacture?

We specialize in manufacturing a wide range of electronic components, including precision parts for smartphones, laptops, circuit boards, enclosures, integrated circuits, switches, and much more. Our expertise covers both small and large-scale production of high-quality CNC machined parts for various electronics applications.

Q: What materials do you use for CNC machining electronic components?

We work with a broad range of materials suitable for electronics, including metals like aluminum, copper, stainless steel, and plastics such as POM, ABS, and PC. Each material is selected based on its suitability for specific performance, durability, and thermal conductivity requirements.

Q: How do you ensure the quality of electronic parts during manufacturing?

At JXD Machining, we implement strict quality control processes, including dimensional inspection, surface finish analysis, and material testing, to ensure all parts meet high-quality standards. Our team follows ISO 9001:2015 and other certifications to deliver consistent, reliable products that meet customer expectations.

Q:Can JXD Machining handle low-volume and high-volume production for electronic parts?

Yes! Whether you need low-volume prototypes or large-scale production, we have the capacity and flexibility to meet your specific needs. We ensure efficient processes, fast turnaround times, and cost-effective solutions, regardless of the order size.

Q: What is the typical lead time for CNC machining electronic components?

Lead times vary depending on the complexity and quantity of your order. However, for prototypes, we typically deliver within 5–7 business days, and for mass production, we strive to meet your deadlines while ensuring the highest quality standards.

Q:How do you support custom design requests for electronic parts?

Our team works closely with you during the design phase, offering expert guidance on material selection, manufacturability, and optimization. We ensure that your custom designs are fully realized, whether through prototyping or production, and provide ongoing support to meet your technical requirements.