What is CNC Machining for Industrial Equipment?

CNC machining is essential for manufacturing high-precision parts used in industrial equipment, from machinery components to structural elements. Whether it’s custom gears, shafts, or housings, our advanced CNC processes deliver durability and consistent performance, ensuring your equipment operates at optimal efficiency.

What We Can Do for You

JXD Machining provides CNC services tailored to the needs of the industrial equipment sector, ensuring that all components meet your exact specifications. Our capabilities include:

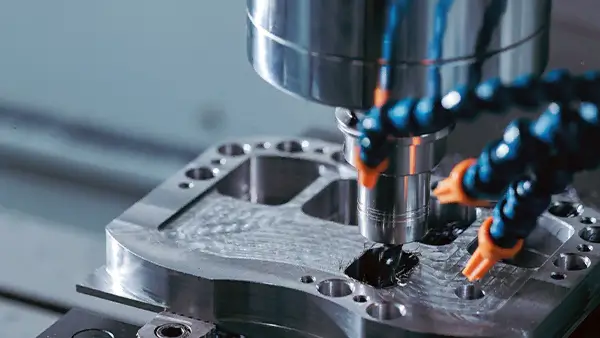

CNC Milling Services

Accurately produce intricate geometries with our advanced CNC milling capabilities, ideal for aerospace, automotive, and electronics industries

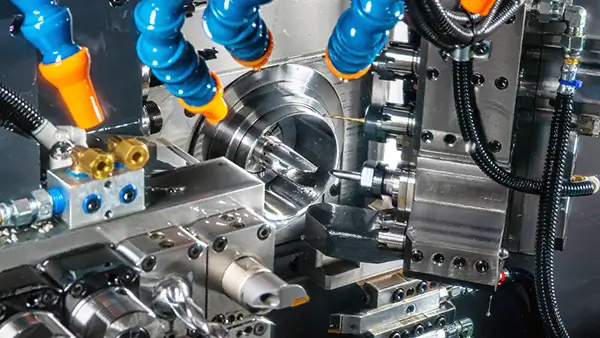

CNC Turning Services

Efficiently manufacture cylindrical parts with tight tolerances and smooth finishes, perfect for shafts, bushings, and custom fittings.

Swiss CNC Machining

Perfect for intricate, small components requiring high precision.

EDM Machining

For intricate cuts and shapes in hard metals, including complex molds.

High-Quality Materials

Each material is chosen based on the required performance, durability, and cost-effectiveness for your industrial equipment parts.

Strong, durable, and versatile for various applications in industrial equipment.

Our Process for Industrial Equipment Parts

Applications in Industrial Equipment

FAQ

1. What types of industrial equipment parts can you manufacture?

We manufacture a wide variety of parts for industrial machinery, including gears, shafts, housings, brackets, pistons, and more.

2. Can you handle both small and large production volumes?

Yes, we have the capacity for both small-batch prototyping and large-scale production runs, depending on your project requirements.

3. What materials do you recommend for industrial equipment parts?

We recommend materials such as stainless steel, aluminum, and titanium, depending on your application’s performance and durability needs.

4. What is your lead time for CNC machining industrial equipment parts?

Lead times depend on the complexity and volume of the parts, but we typically deliver prototypes within 5-7 business days, and mass production within 10-15 business days.

5. How do you ensure the quality of CNC machined parts?

We implement strict quality control measures, including dimensional checks, material testing, and post-production inspection, to ensure every part meets your specifications.