Industry-Leading Precision for Medical Parts

In the medical industry, precision is critical. We provide CNC machining services with tolerances as tight as ±0.01 mm to meet the highest standards for medical device components. From surgical tools to implantable devices, we deliver parts that perform reliably and safely, ensuring quality at every step, from prototyping to final production. Our quality assurance system includes rigorous inspections, traceability, and compliance with ISO 13485 and FDA regulations, ensuring every part meets the necessary medical-grade standards.

Compliant Materials for Medical Components

Material compliance is a non-negotiable requirement for medical device manufacturing. We provide medical-grade materials, including titanium, stainless steel, PEEK, and other biocompatible materials, all conforming to FDA, ISO 13485, and other global standards. Whether you require corrosion-resistant alloys, bio-safe plastics, or precision-engineered metals, we ensure all materials used meet the strictest regulations for medical applications.

Capable of Manufacturing Complex Medical Components

Medical devices often require components with complex geometries that demand the highest level of precision. Our capabilities in 3-axis, 4-axis, and 5-axis CNC machining allow us to deliver intricate designs, whether for orthopedic implants, surgical tools, or diagnostic devices. With advanced CNC equipment and highly skilled engineers, we can produce components with intricate features and tight tolerances that other methods may not be able to achieve.

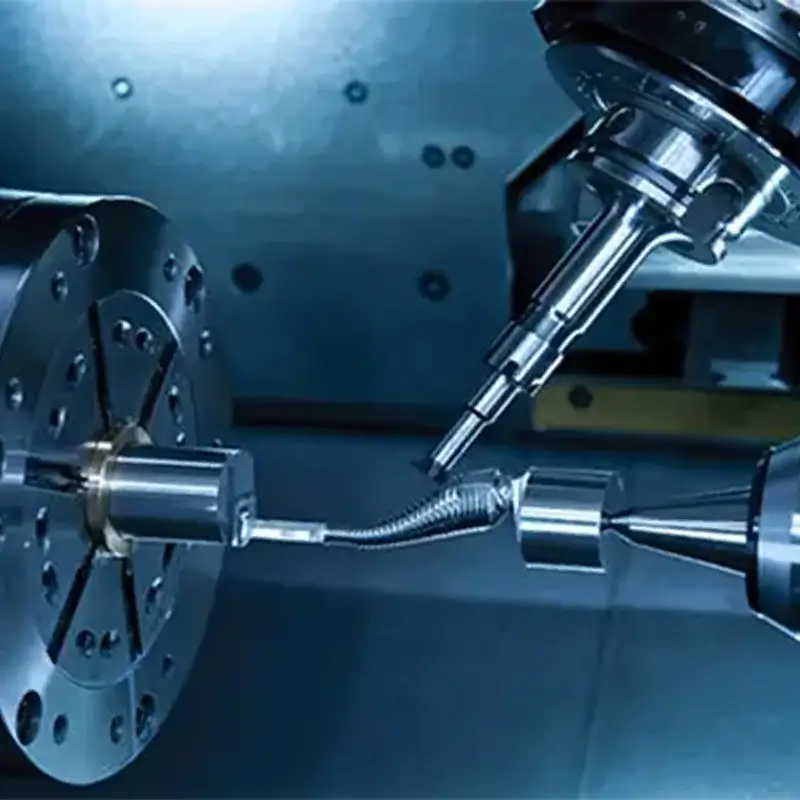

5-Axis CNC Machining

5-axis CNC machining enhances complex medical device production with superior precision, reduced setup times, and cost-effective multi-angle processing.

Medical Part with Complex Geometries

Intricate medical parts with complex geometries, such as implants, surgical instruments, and prosthetics, require precise CNC machining techniques and tools.

Intellectual Property Protection

Protecting your intellectual property is a priority. At JXD Machining, we understand that your medical device designs are valuable and proprietary. We implement strict confidentiality agreements and secure processes to safeguard your designs from unauthorized access or disclosure. Our non-disclosure agreements (NDAs) ensure that your designs remain secure throughout the prototyping and manufacturing process.

FAQ

1. What materials are commonly used for CNC machining medical devices?

We use high-quality materials like stainless steel, titanium, PEEK, and medical-grade plastics. All materials comply with ISO 13485 and FDA standards.

2. What are the typical tolerances you can achieve for medical parts?

We can achieve tolerances as tight as ±0.01 mm, ensuring high precision for even the most complex medical components.

3. Do you offer prototyping services for medical device parts?

Yes, we provide rapid prototyping services, allowing you to test and validate your designs before moving to full-scale production.

4. How do you ensure the quality of medical parts?

Our quality control process includes dimensional inspections, material certifications, and compliance with FDA and ISO 13485 standards to ensure every part meets medical-grade requirements.

5. Can you help with design optimization for medical parts?

Absolutely! Our engineers work closely with you to optimize your design for manufacturability, cost-effectiveness, and functionality, ensuring the highest quality and performance.