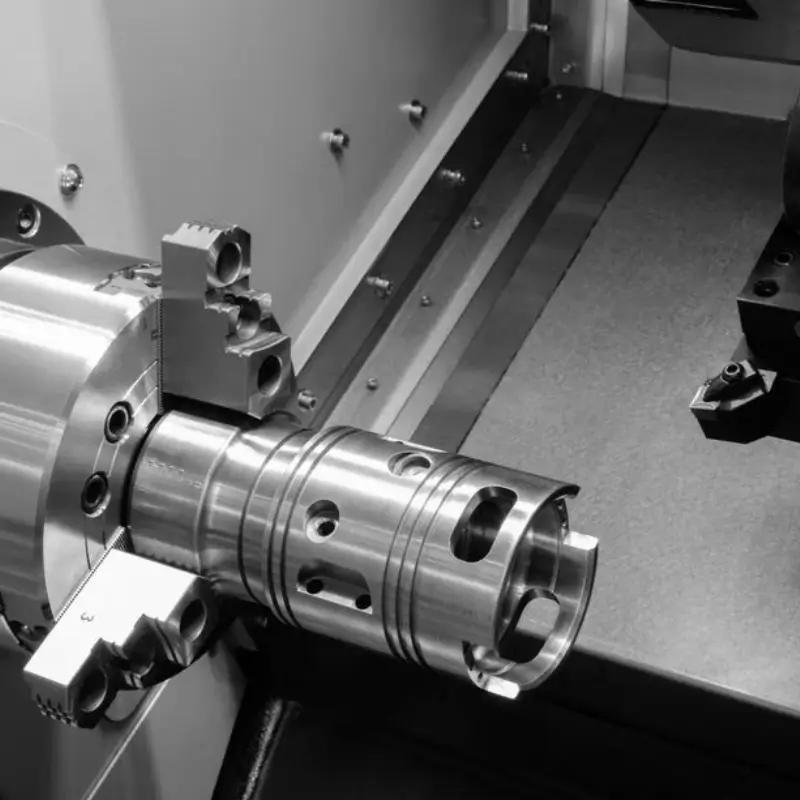

Stainless Steel CNC Machining Services

Precision-crafted stainless steel parts with superior strength, corrosion resistance, and a flawless finish—perfect for demanding applications across industries.

• High Strength & Durability

• Corrosion Resistance

• Wide Material Options

• Precision Manufacturing ±0.01mm

Stainless Steel Material

Stainless steel is a versatile material renowned for its exceptional strength, corrosion resistance, and durability, making it an ideal choice for CNC machining. Its unique properties allow for precision machining of components across industries such as aerospace, medical, automotive, and food processing. CNC machining enhances the material’s natural characteristics, delivering high-precision parts with excellent surface finishes and tight tolerances.

Stainless Steel CNC Machining Tolerances

Our state-of-the-art CNC machining processes are designed to deliver stainless steel parts with precision and reliability. We adhere to international quality standards, ensuring every part meets your exact specifications.

| Parameter | Typical Tolerance | High-Precision Tolerance | Application Examples |

|---|---|---|---|

| Dimensional Accuracy | ±0.05 mm | ±0.01 mm | Aerospace, medical, and defense components |

| Surface Roughness (Ra) | 1.6 μm – 3.2 μm | 0.8 μm – 1.6 μm | Polished, aesthetic, or functional surfaces |

| Hole Diameter Accuracy | ±0.05 mm | ±0.01 mm | Precision-fitted parts and fasteners |

| Flatness | ≤0.02 mm per 100 mm | ≤0.01 mm per 100 mm | Sealing faces, critical contact areas |

| Thread Tolerance | ISO 6g/6H | ISO 4g/4H | High-precision threads for assemblies |

Optimized Comparison of Common Stainless Steel Alloys

Magnesium alloys combine lightweight properties, corrosion resistance, and machinability, making them perfect for aerospace, automotive, and industrial CNC machining projects.

| Grade | Corrosion Resistance | Strength | Hardness (HRB) | Machinability (%) | Weldability | Key Applications | Features & Advantages |

|---|---|---|---|---|---|---|---|

| 304 | High (general use) | Moderate | 70–90 | 0.7 | Excellent | Food processing, piping, kitchen equipment | Widely used, excellent corrosion resistance, suitable for general-purpose applications. |

| 316 | Superior (marine/chemical) | Moderate | 70–90 | 0.5 | Excellent | Marine parts, chemical tanks, medical devices | Best for chloride-rich environments, resistant to chemical corrosion and pitting, biocompatible. |

| 303 | Moderate | Moderate | 70–80 | 0.78 | Limited | Screws, bolts, fittings | Free-machining stainless steel, excellent machinability with reasonable corrosion resistance. |

| 17-4 PH | Moderate | High (1100 MPa tensile) | 260–280 (hardened) | 0.55 | Limited | Aerospace components, valve parts, molds | Precipitation-hardened, high strength, excellent dimensional stability under heat-treated conditions. |

| 420 | Moderate | High | 180–230 | 0.4 | Limited | Surgical instruments, knives, molds | Hardenable for cutting and wear applications, offers high polishability and edge retention. |

| 416 | Moderate | Moderate | 149 | 0.85 | Limited | Gears, shafts, bolts | Best machinability among stainless steels due to added sulfur; suitable for components needing fast turnaround. |

| 430 | Moderate (non-marine) | Low | 70–85 | 0.6 | Good | Decorative trim, appliance components | Economical ferritic stainless steel for non-demanding applications; great for corrosion-free environments. |

Surface Finishing for CNC Machined Parts

JXD-Machining provides diverse surface finishing options to enhance the appearance, durability, and performance of CNC machined parts, meeting both functional and aesthetic needs.

Anodizing

A durable and corrosion-resistant finish that enhances the aluminum part’s surface while providing an aesthetic appearance. Ideal for improving wear resistance and offering a wide range of color options.

Black Oxide

A chemical coating that provides moderate corrosion resistance and a sleek black appearance, often used for steel parts to reduce glare and improve aesthetic appeal.

Sandblasting + Type II Anodizing

Combines a matte finish from sandblasting with Type II anodizing to create a smooth, uniform surface that is corrosion-resistant and visually appealing.

Sandblasting + Type III Anodizing (Hard Coat)

A more robust version of anodizing combined with sandblasting, offering excellent wear and corrosion resistance for applications requiring durability under harsh conditions.

Polishing

Enhances the surface of parts by removing minor imperfections, resulting in a smooth and shiny finish that improves aesthetic appeal and surface cleanliness.

Passivation

Passivation enhances corrosion resistance by removing surface contaminants and forming a protective oxide layer. Ideal for stainless steel, it ensures durability, cleanliness, and long-term performance in industries like aerospace and medical devices.

Sandblasting

Uses abrasive particles to create a uniform matte texture on the part’s surface, ideal for preparing parts for subsequent coatings or achieving a visually attractive finish.

Tumbling

A mechanical finishing process that smoothens and polishes parts by rotating them in a tumbler with abrasives, suitable for deburring and improving surface texture.

Heat Treatment

Enhances the mechanical properties of metal parts, such as hardness, toughness, and wear resistance, by heating and cooling them under controlled conditions.

Powder Coating

Applies a durable and uniform layer of colored polymer powder, offering excellent protection against corrosion, UV damage, and general wear and tear.

Electroplating

A process of depositing a thin metal layer, such as nickel or chrome, onto a part’s surface to improve its appearance, corrosion resistance, and durability.

Laser Engraving

Uses focused laser beams to etch designs, text, or markings onto parts with high precision, providing permanent and highly detailed customizations.

Learn more about our metal and plastic surface finishing capabilities here.

FAQs for Stainless Steel CNC Machining Page

1. What are the most commonly used stainless steel grades for CNC machining?

We frequently machine grades like 304, 316, 303, 17-4 PH, and 420. Each grade is chosen based on its unique properties, such as corrosion resistance, strength, and application suitability.

2. Can stainless steel be precision-machined for tight tolerances?

Yes, our advanced CNC machining technology achieves tolerances as tight as ±0.005mm for stainless steel parts, ensuring precision for even the most complex designs.

3. What surface finishes are available for stainless steel CNC parts?

We offer a variety of finishes, including polishing, passivation, bead blasting, and electropolishing, to enhance aesthetics, durability, and functionality.

4. How do I choose the right stainless steel grade for my project?

Consider the operating environment, mechanical strength requirements, and specific features like corrosion resistance. For example, 316 is ideal for marine applications, while 303 offers excellent machinability for precision components.

5. What industries commonly use stainless steel CNC machined parts?

Stainless steel is widely used in industries such as aerospace, medical, food processing, marine, and automotive due to its durability, hygiene, and corrosion resistance.

6. Can you provide material certifications for stainless steel parts?

Yes, we provide mill test reports (MTRs) and other certifications upon request to ensure compliance with quality standards and project requirements.