Plastic Material

Our CNC plastic machining services provide exceptional quality for a wide range of materials, each selected for its unique properties to meet your specific project requirements.

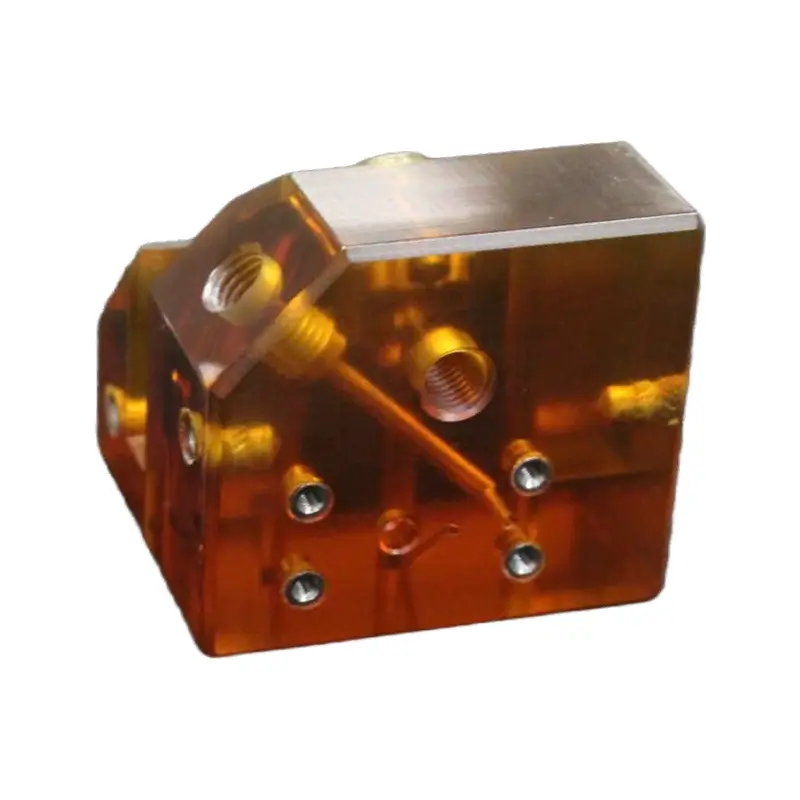

Plastic Machining Process

Plastic CNC Milling

Versatile and precise, milling produces intricate parts with tight tolerances, ideal for aerospace, automotive, and medical applications.

Plastic CNC Turning

Perfect for cylindrical components, turning delivers smooth finishes and consistent precision for shafts, bushings, and fittings.

CNC Machining or 3D Printing? A Practical Guide to Choosing the Right Process

Selecting between CNC plastic machining and 3D printing depends on your project requirements. Each has its unique strengths:

When CNC Plastic Machining Is the Better Choice

• Precision Is Critical: CNC offers high tolerances (±0.01mm), ideal for parts requiring fine detail and tight specifications.

• Material Properties Matter: Engineering plastics like PEEK and PTFE can retain their full performance only when CNC-machined.

• Volume Production: CNC is cost-efficient for medium to large production runs, ensuring consistent quality across batches.

• Durability and Strength: Perfect for structural components like medical devices, automotive parts, and aerospace applications.

When 3D Printing Excels

• Rapid Prototyping: It allows for fast iterations to validate designs or test functionality.

• Complex Geometries: 3D printing excels at producing intricate shapes without the need for additional tooling.

• Low-Volume Production: Suitable for producing limited quantities on a tight budget.

• Less Demanding Material Needs: Works well for general-purpose plastics and resin parts.

*Tip: For projects requiring both, consider starting with 3D printing for prototypes and shifting to CNC for high-precision production. If you are unsure, our experts will guide you. Please contact us.

The Advantages of CNC Plastic Machining

Exceptional Precision and Consistency

CNC machining achieves tight tolerances (±0.01mm) and smooth finishes, delivering parts ready for immediate use. This is particularly critical in industries like aerospace, automotive, and medical equipment.

Wide Range of Material Compatibility

CNC supports various engineering plastics such as PA, ABS, PEEK, PTFE, and POM. Each material offers unique properties, from high strength to chemical resistance, catering to diverse project needs.

High Efficiency for Volume Production

Once programmed, CNC machines can produce hundreds or thousands of parts with identical quality, optimizing costs for larger production runs.

Durability and Surface Quality

CNC-machined parts exhibit excellent strength and can undergo additional surface treatments like polishing or coating, enhancing their durability and appearance.

Find the Perfect CNC Plastic Material for Your Parts

Selecting the right CNC plastic material is crucial to achieving the perfect balance between performance, durability, and cost-effectiveness for your components. Here’s how to make an informed decision:

1. Define Application Requirements

Identify your part’s operating conditions, including temperature, mechanical stress, and exposure to chemicals. For instance:

• High strength and impact resistance? POM (Delrin) or ABS may be ideal.

• Extreme heat resistance? PEEK or PTFE should be considered.

2. Evaluate Precision and Tolerance Needs

Materials like PAI and PEI are excellent for tight tolerances and intricate geometries, commonly required in aerospace or medical applications.

3. Consider Surface Finish and Aesthetic Preferences

If the visual appearance or surface quality is critical, materials like PMMA (Acrylic) are perfect for transparent or polished finishes.

4. Analyze Cost vs. Performance

• For high-performance needs within budget constraints, HDPE and ABS offer great value.

• For premium applications, PEEK delivers unmatched performance, albeit at a higher cost.

5. Understand Machinability

Certain plastics, such as POM and ABS, are easier to machine, leading to faster production and lower costs. For more complex designs, materials with high machinability ensure precision and efficiency.

6. Consult with Experts

When in doubt, collaborate with CNC specialists to select the best material based on your project’s unique requirements, ensuring optimal performance and cost-effectiveness.

FAQ

1. What is the lead time for CNC plastic machining?

Our typical lead time is 3–7 days, depending on the project complexity and volume.

2. Do you provide custom surface finishes for plastic parts?

Yes, we offer polishing, texturing, and other custom finishes based on your specifications.

3. Can you work with recycled or eco-friendly plastics?

Absolutely! We can source sustainable materials upon request.

4. How do you ensure tight tolerances for plastic components?

Our advanced CNC equipment and quality control measures guarantee tolerances as precise as ±0.01 mm.

5. What is the maximum part size for CNC plastic machining?

We can machine parts up to 1000 mm in size, depending on the material.