Precision and Durability with ABS CNC Machining

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic known for its strength, durability, and ease of machining. Ideal for custom CNC machining, ABS provides excellent performance in a wide variety of industries, from automotive to electronics

• Excellent impact resistance

• Good dimensional stability

• Easy to machine and fabricate

• High chemical resistance

• Affordable and widely available

About ABS

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic polymer known for its exceptional strength, durability, and ease of machining. This versatile material is made from three primary components: acrylonitrile, butadiene, and styrene. ABS is favored across various industries due to its excellent balance of impact resistance, machinability, and affordability, making it ideal for a wide range of applications.

• Acrylonitrile provides chemical resistance and enhances thermal stability.

• Butadiene contributes to toughness, offering superior impact resistance.

• Styrene provides rigidity and ease of processing, enhancing aesthetic qualities.

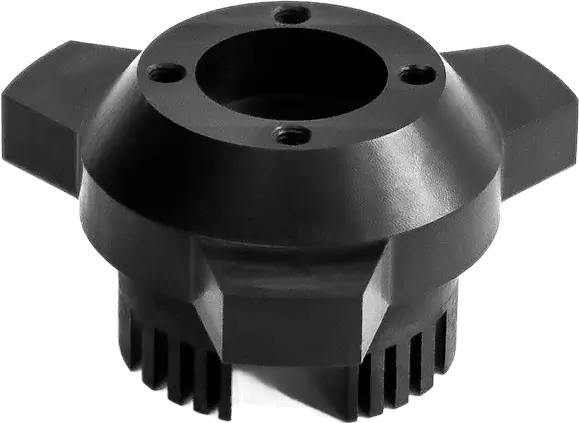

ABS is commonly used for manufacturing parts such as casings, housings, and enclosures, making it a reliable choice for products in consumer electronics, automotive, and industrial applications. The material’s strong impact resistance and easy machining properties allow for the production of high-quality custom parts with precision and efficiency.

Key Performance Metrics of ABS in CNC Machining

Material selection can be the difference between success and failure for any project. Educate yourself on material properties to make sure you use them in a way that brings optimal results.

| Property | Tensile Strength | Flexural Modulus | Impact Resistance | Heat Deflection Temperature | Density | Molding Shrinkage | Thermal Conductivity | Chemical Resistance |

|---|---|---|---|---|---|---|---|---|

| Value | 40 - 50 MPa | 2.0 - 2.5 GPa | High (with high-impact grades) | 90-100°C | 1.04 - 1.06 g/cm³ | 0.5% - 1.5% | 0.2 W/m·K | Excellent (against oils, acids) |

Applications of ABS Material

ABS is widely used across various industries due to its remarkable properties, including excellent impact resistance, high machinability, and chemical resistance. Its versatility makes it suitable for a wide range of applications, from consumer goods to industrial components.

ABS is commonly used for manufacturing durable and aesthetically pleasing parts such as mobile phone cases, laptop housings, and TV enclosures. Its ability to be molded into complex shapes and finished with a smooth surface makes it a popular choice in this sector.

Automotive Parts

ABS is commonly used for manufacturing durable and aesthetically pleasing parts such as mobile phone cases, laptop housings, and TV enclosures. Its ability to be molded into complex shapes and finished with a smooth surface makes it a popular choice in this sector.

In the industrial sector, ABS is used to produce parts like machinery housings, gears, and electrical enclosures. Its high strength and ability to withstand stress make it suitable for high-performance environments.

Toys and Household Products

ABS is used in a variety of consumer goods like toys, kitchenware, and household appliances due to its low cost, ease of processing, and ability to maintain a consistent and attractive finish.

While ABS is not typically used for direct medical contact, it is ideal for producing non-invasive medical device components, such as housings for equipment like thermometers and pulse oximeters, where durability and high impact resistance are crucial.

FAQ

Q: What are the main applications of ABS in CNC machining?

ABS is widely used for manufacturing components in automotive, consumer electronics, appliances, and even medical devices. Its impact resistance and ease of machining make it suitable for a variety of parts like housings, covers, and enclosures.

Q: What is the difference between general-purpose ABS and high-impact ABS?

General-purpose ABS is used for applications requiring standard strength and impact resistance, while high-impact ABS offers superior toughness and is ideal for parts exposed to harsh conditions and frequent wear.

Q: Is ABS suitable for outdoor applications?

While ABS has good resistance to UV rays and weathering, high-impact or UV-resistant ABS grades are recommended for outdoor applications to ensure long-term durability.

Q:Can ABS be welded or glued?

Yes, ABS can be welded using heat or solvent welding, and it can be glued with appropriate adhesives, such as those designed for plastics.

Q: How does ABS compare to other plastics like PVC or polycarbonate?

ABS has better impact resistance and dimensional stability than PVC and is easier to machine than polycarbonate, making it a more cost-effective and versatile choice for many applications.