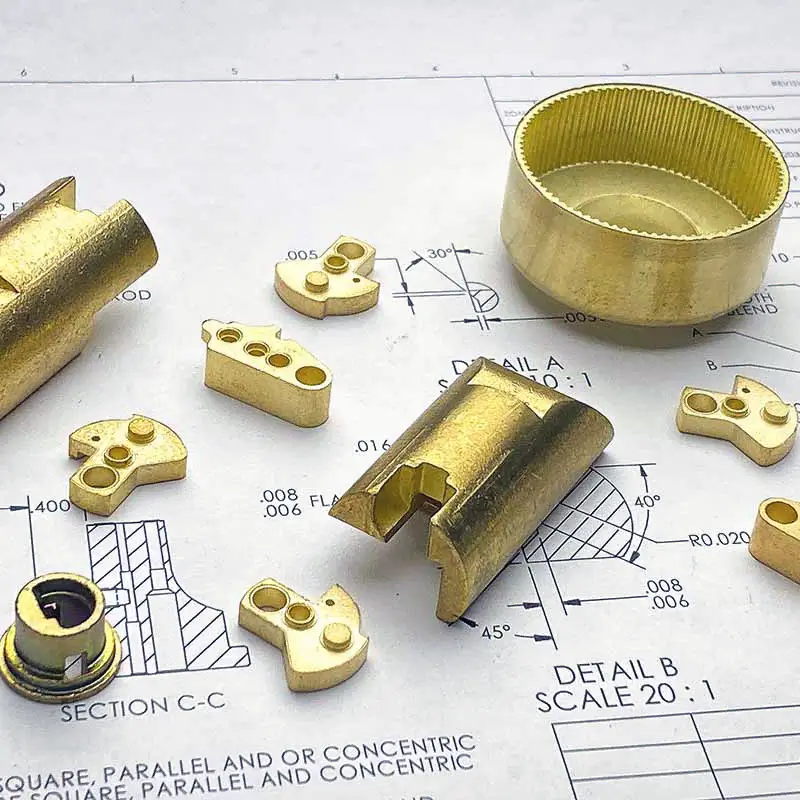

High-Quality Brass CNC Machining for Precision Parts

Our CNC machining services deliver high-performance brass parts tailored to your specifications. Combining precision with durability, we provide efficient and cost-effective solutions for various industries.

• Excellent machinability for complex designs

• High corrosion resistance and durability

• Rapid production and quick lead times

• Versatile for a range of industrial applications

About Brass

Brass is an alloy of copper and zinc, known for its excellent machinability, corrosion resistance, and aesthetic appeal. It is widely used for precision parts and decorative items. Brass has an ideal balance of strength, ductility, and conductivity, making it suitable for various industrial applications. Its versatile properties allow it to be used in applications from electrical connectors to mechanical components.

Composition and Features:

• Composition: Primarily composed of copper (Cu) and zinc (Zn), with small amounts of other metals like lead (Pb), tin (Sn), and arsenic (As) to improve its properties.

Features:

• Good electrical conductivity

• High corrosion resistance

• Excellent machinability

• High strength and durability

• Attractive surface appearance, suitable for decorative parts

Brass Alloy Comparison

Brass alloys come in different grades and compositions, each with unique characteristics suited for various applications. Below is a comparison of common brass alloys to help you select the right material for your specific needs.

| Brass Alloy | Composition (Cu/Zn) | Strength (MPa) | Hardness (Brinell) | Weldability | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|---|

| C36000 | 63% Cu / 35% Zn | 250-500 | 90-160 | High | Moderate | Electrical connectors, valves, pneumatic components |

| C37700 | 58% Cu / 39% Zn | 250-400 | 80-130 | Medium | Good | Plumbing fittings, mechanical connectors |

| C26000 | 70% Cu / 30% Zn | 200-350 | 80-110 | High | Excellent | Precision tools, electronic contact parts |

| C27000 | 65% Cu / 35% Zn | 180-300 | 75-100 | Medium | Good | Gears, low-load parts |

| C22800 | 85% Cu / 15% Zn | 320-450 | 100-150 | Low | Good | High-strength structural components |

Applications

FAQ

1. What is the main difference between brass and copper?

Brass is an alloy of copper and zinc, offering enhanced strength and corrosion resistance compared to pure copper. It is also easier to machine, making it ideal for precision parts.

2. Can brass be used for marine applications?

Yes, brass is highly resistant to corrosion, especially in seawater, and is commonly used for marine fittings and valves.

3. What brass alloy is best for CNC machining?

For CNC machining, alloys like C36000 and C26000 are popular due to their excellent machinability and high strength-to-weight ratio.

4. Can brass be welded?

Yes, brass can be welded, and it is often used for components that need to undergo welding processes, especially in plumbing and mechanical parts.

5. How can brass be further processed after CNC machining?

Brass parts can undergo various surface treatments, including polishing, anodizing, and electroplating, to improve their appearance, corrosion resistance, and overall performance.