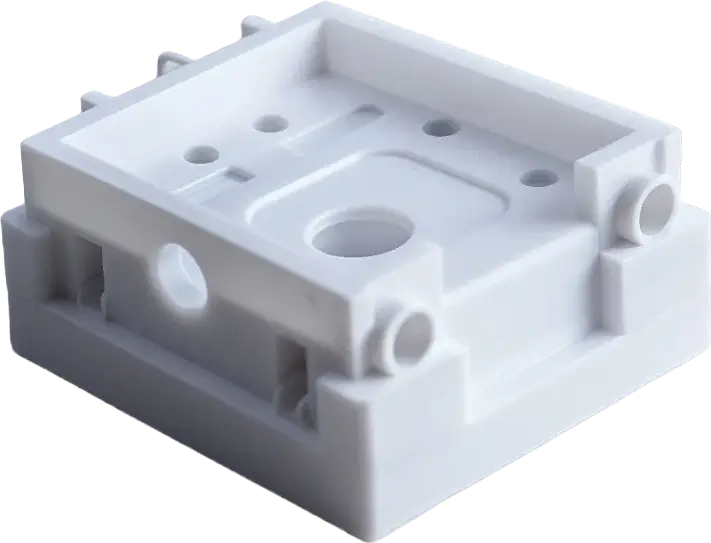

Precision CNC Machining for High-Density Polyethylene (HDPE)

We provide high-quality HDPE CNC machining services for custom parts and components. With superior durability, excellent chemical resistance, and easy machinability, HDPE is ideal for a wide range of industrial applications

·Certification materials

·Factory price

·Rapid turnover

·Precision machining

About HDPE

High-Density Polyethylene (HDPE) is one of the most widely used plastics, known for its strength, durability, and versatility. HDPE is a thermoplastic made from petroleum, and it is commonly used in a variety of applications that require chemical resistance, high tensile strength, and impact resistance

• High Durability

• Chemical Resistance

• Low Moisture Absorption

• High Tensile Strength

• Environmentally Friendly

CNC Machining Services for Precision HDPE Parts

We offer a full range of CNC machining services for HDPE, from prototyping to large-scale production. Whether you need intricate parts or robust components, our precision machining processes ensure consistent, high-quality results

Precision CNC milling for complex parts with tight tolerances, perfect for metal and plastic components

High-accuracy CNC turning for cylindrical parts, delivering smooth finishes and consistent quality

Polishing & Finishing

Comprehensive surface finishing options like polishing, anodizing, and plating to enhance durability and appearance

HDPE Applications

HDPE is used in a wide range of industries due to its excellent mechanical properties, chemical resistance, and durability

HDPE is used in parts like fuel tanks, bumpers, and under-the-hood components due to its strength and chemical resistance

HDPE is commonly used in the production of bottles, containers, and plastic bags due to its lightweight and durable properties

In construction, HDPE is used for piping systems, plastic lumber, and drainage systems, offering long-lasting performance

HDPE is a popular material in the food industry for containers, packaging, and cutting boards, where food-safe materials are required.

Due to its strength and chemical resistance, HDPE is also used for medical components like prosthetics and surgical tools

FAQ

Q: What is HDPE used for in CNC machining?

HDPE is commonly used in CNC machining for parts that require durability, chemical resistance, and low friction. Applications include automotive parts, medical devices, food containers, and piping systems.

Q: What are the advantages of machining HDPE?

HDPE offers advantages like low moisture absorption, chemical resistance, impact resistance, and ease of machining. These properties make it ideal for CNC machining and a range of industrial applications.

Q: Can HDPE be used for high-stress applications?

Yes, HDPE is a strong and durable material that can withstand mechanical stress. It is ideal for applications requiring strength, but it is more commonly used in moderate stress environments compared to metals.

Q: What CNC services are available for HDPE?

We provide CNC milling, turning, routing, drilling, tapping, and prototyping services for HDPE. Our services cater to both small batches and high-volume production.

Q: Is HDPE a sustainable material?

Yes, HDPE is 100% recyclable, making it an environmentally friendly material choice for various applications. Many HDPE products are recycled into new products, reducing waste and promoting sustainability.