Titanium CNC Machining Services

High-performance Titanium Parts, Precision Machining, and Custom Solutions for Demanding Industries.

·Save 30% cost on average!

·Certified Materials

·Factory Price

·No Minimum Order

Understanding Titanium Materials for CNC Machining

Titanium alloys are renowned for their durability and ability to withstand harsh environments. While Grade 5 (Ti-6Al-4V) is one of the most popular titanium alloys, we also specialize in other grades like Grade 2 for medical applications and Grade 23 for high-stress, high-performance needs. Choosing the right grade for your project is crucial to achieving the best performance and ensuring the part’s longevity.

Here are some of the key benefits of titanium materials:

• Strength-to-Weight Ratio: Titanium alloys offer an excellent balance between strength and weight, making them perfect for lightweight, high-stress applications.

• Corrosion Resistance: Titanium is highly resistant to corrosion, especially in harsh environments like seawater or acidic solutions.

• Durability: With its ability to perform under extreme conditions, titanium is ideal for parts that need to endure high pressure, temperature, or fatigue.

• Biocompatibility: Titanium is non-toxic and well-suited for medical implants and devices, where compatibility with the human body is a critical concern.

Common Steel Grades for CNC Machining

We work with a variety of titanium alloys, each with unique characteristics suited for different applications. Here’s a comparison of common grades of titanium used in CNC machining to help you choose the best material for your project.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Vickers) | Applications | Features |

|---|---|---|---|---|---|

| Grade 5 (Ti-6Al-4V) | 900 | 830 | 370 | Aerospace, Medical, Automotive | High strength, good corrosion resistance, lightweight |

| Grade 23 | 930 | 380 | 200 | Medical, Chemical Processing | Excellent corrosion resistance, weldable, biocompatible |

| Grade 23 (Ti-6Al-4V ELI) | 880 | 830 | 350 | Aerospace, Medical Implants | Extra-low interstitials, ideal for high-performance applications |

| Grade 9 (Ti-3Al-2.5V) | 825 | 720 | 280 | Marine, Aerospace | Lightweight, excellent fatigue resistance, high strength |

| Grade 5 Titanium | 900 | 830 | 370 | Aerospace, Automotive | Widely used, strong, resistant to corrosion, easy to machine |

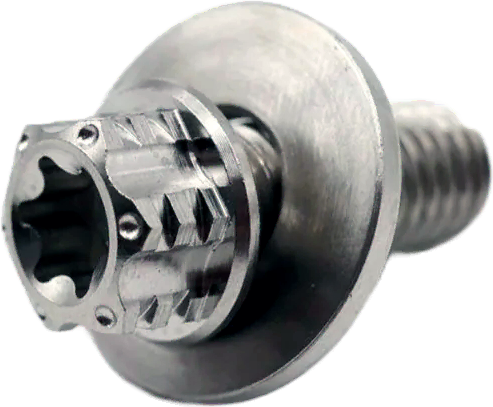

Our Titanium CNC Machining Capabilities

At JXD Machining, we specialize in machining titanium alloys with high precision and efficiency. Using advanced CNC technology, we can produce intricate titanium components with tight tolerances and superior surface finishes. Our team has experience working with various grades of titanium to meet the unique needs of each project.

| Capability | Details |

|---|---|

| CNC Machines | 3-axis, 4-axis, and 5-axis CNC milling and turning machines |

| Tolerances | Achieve tolerances as tight as ±0.005 mm |

| Surface Finishing | Anodizing, polishing, sandblasting, and coating options |

| Materials Supported | Grade 5, Grade 2, Grade 9, and Grade 23 titanium alloys |

| Production Volume | Prototype to low and high-volume production capabilities |

| Applications | Aerospace, automotive, medical, and industrial parts |

Titanium CNC Machining Applications

Titanium is used in a wide range of industries due to its strength, corrosion resistance, and biocompatibility. Below are some of the key applications and parts made from titanium that are commonly produced using CNC machining.

·Aerospace Aircraft frames, turbine blades, engine components, landing gear

·Medical Surgical instruments, medical implants, prosthetics, dental implants

·Automotive Engine components, suspension parts, performance components

·Marine Propellers, boat hulls, underwater tools, marine hardware

·Industrial Valves, seals, pressure vessels, pumps, fluid handling systems

·Chemical Pressure vessels, reactors, piping, heat exchangers

Surface Finishes For CNC Machined Titanium Parts

JXD-Machining can provide the perfect finishing touch to your CNC-machined titanium parts with a range of Anodizing, Polishing, Passivation, Bead Blasted, Powder Coat, and Plating options. Each finish offers its own advantages – so make sure you select the one that meets all your requirements!

Anodizing

Titanium anodizing is a process that creates a protective oxide layer on the surface of titanium, enhancing its resistance to corrosion, wear, and environmental factors. It also allows for coloring, adding aesthetic appeal while maintaining its durability.

Polishing

Titanium polishing smoothens the surface of titanium parts, removing imperfections and giving them a shiny, reflective finish. This process improves the visual appeal and ensures the parts meet the required surface quality standards.

Passivation

Passivation is a treatment that forms a thin oxide layer on the surface of titanium, improving its corrosion resistance and biocompatibility. It is commonly used for parts exposed to harsh environments or in medical applications where safety and durability are critical.

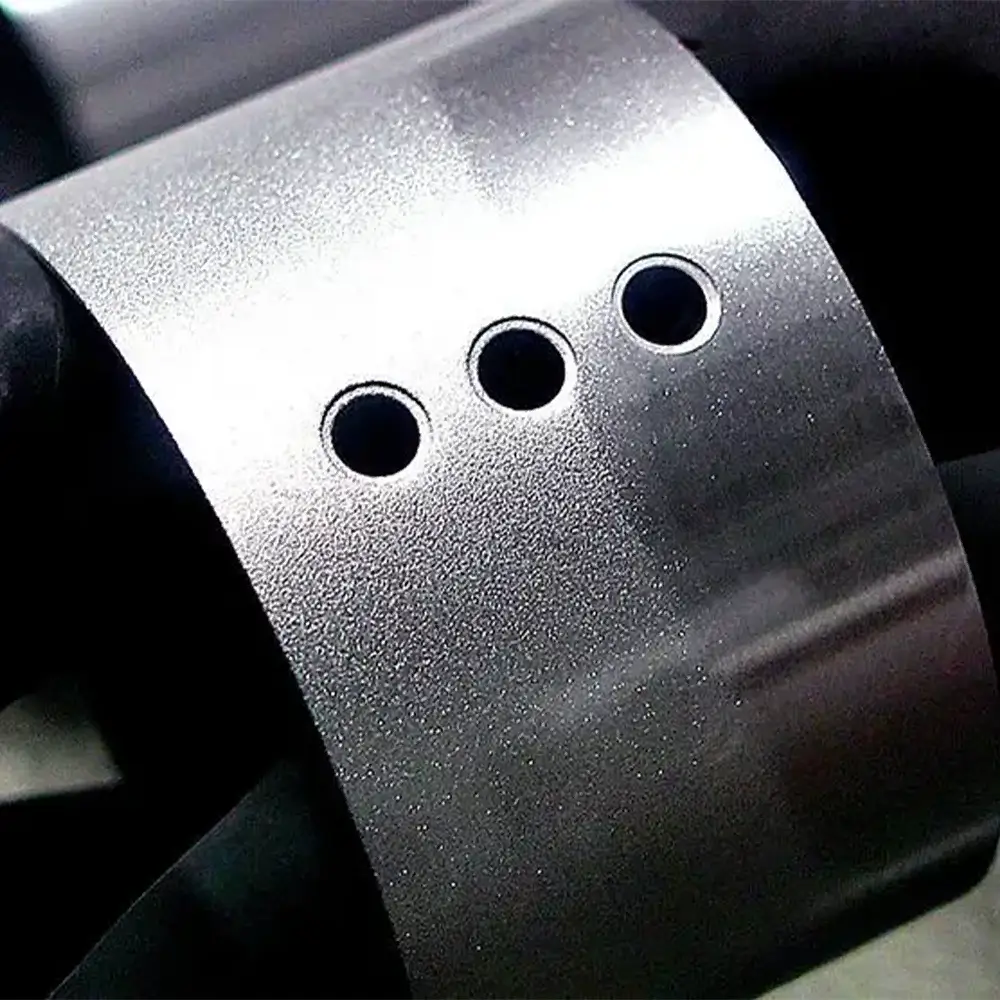

Bead Blasting

Bead blasting is a technique where small glass or ceramic beads are blasted onto titanium surfaces at high speed. This creates a uniform, matte finish, which improves texture and reduces reflectivity, making the parts look more refined.

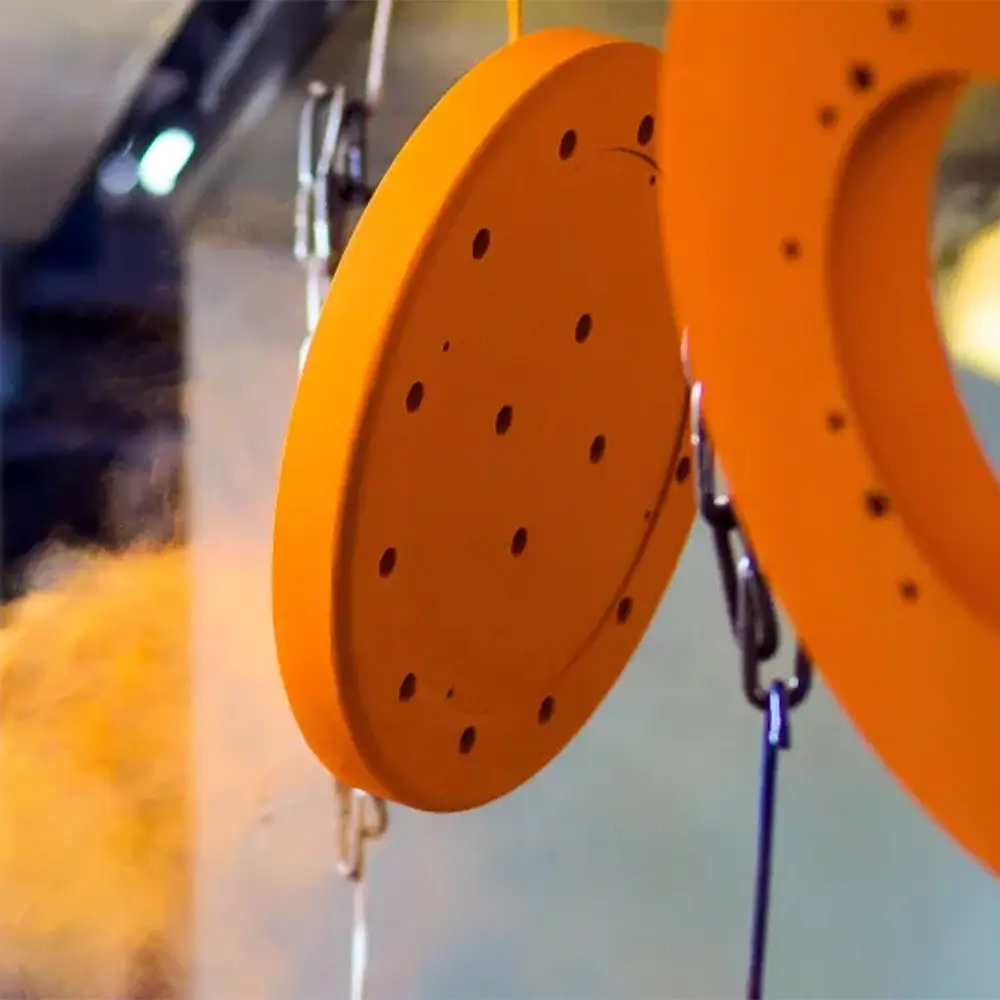

Powder Coating

Powder coating applies a protective and decorative coating to titanium parts. A dry powder is sprayed onto the surface and baked, creating a durable, corrosion-resistant finish that adds color and ensures longevity.

Plating

Plating involves applying a thin layer of metal onto the titanium surface to enhance its appearance, improve corrosion resistance, and increase conductivity or other material properties, depending on the specific needs of the part.

Learn more about our metal and plastic surface finishing capabilities here.

FAQ

1. What are the benefits of titanium over other metals?

Titanium is known for its superior strength-to-weight ratio, corrosion resistance, and biocompatibility, making it ideal for aerospace, medical, and marine applications. It is particularly effective in environments that demand durability and reliability.

2. What are the most common grades of titanium used in CNC machining?

The most common grades are Grade 5 (Ti-6Al-4V), Grade 2, and Grade 23. Each offers different properties suited for various industries such as aerospace, medical, and automotive.

3. What is the maximum size of titanium parts you can machine?

We can machine titanium parts of varying sizes depending on the complexity and requirements of the project. Please contact us with your specifications, and we’ll provide more details.

4. Do you offer surface treatments for titanium parts?

Yes, we offer various surface treatments such as anodizing, polishing, and coating to improve the appearance, durability, and corrosion resistance of titanium parts.

5. What industries do you serve with titanium CNC machining?

We serve aerospace, medical, automotive, marine, and industrial sectors. Our titanium part