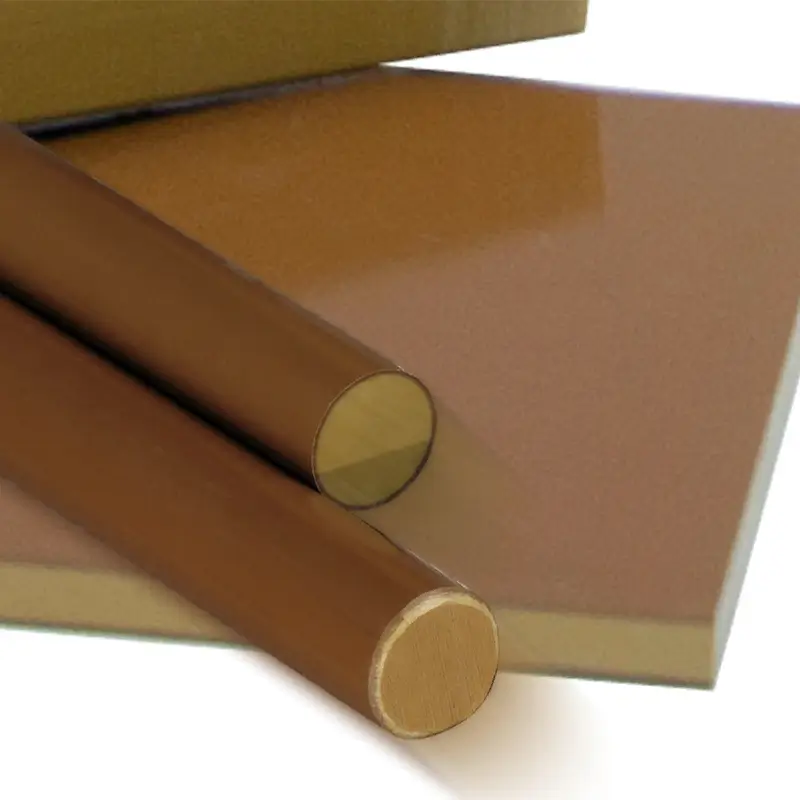

Precision CNC Machining for High-Performance PAI Components

Our PAI (Polyamide-imide) CNC machining services deliver high-strength, high-temperature resistance parts with superior mechanical properties. Ideal for demanding applications in industries such as aerospace, automotive, and electronics

·Certification materials

·Factory price

·Rapid turnover

·Precision machining

About Polyamide (PA)

PAI (Polyamide-imide) is an advanced engineering thermoplastic known for its exceptional mechanical strength, chemical resistance, and high-temperature performance. It is a high-performance material commonly used in industries such as aerospace, automotive, and electronics. PAI exhibits excellent wear resistance, dimensional stability, and the ability to withstand temperatures up to 260°C (500°F) without losing its mechanical properties.

This material is an ideal choice for CNC machining, as it is easy to process, delivers high precision, and holds tight tolerances even under extreme conditions. PAI is widely used for applications requiring high-performance parts that can operate in demanding environments

• High Temperature Resistance

• Superior Strength

• Wear and Abrasion Resistance

• Chemical Resistance:

• Low Friction

Common PAI Grades and Their Applications

Polyamide-imide (PAI) is a high-performance engineering plastic widely used in applications that require excellent mechanical properties, high temperature resistance, and chemical resistance. The most common grades of PAI are unfilled, retaining their inherent excellent characteristics, making them ideal for demanding industrial environments.

Common PAI materials include Torlon 4203, Torlon 4503, Torlon 4301, and Torlon 4501. These materials are produced by Solvay and branded as “Torlon,” offering exceptional durability and high performance

Torlon 4203 is a PAI grade known for its high toughness and excellent impact resistance. It is often used in parts requiring electrical insulation and radiation resistance. Typical applications include insulators, seals, gaskets, pump, and valve components, as well as other parts where electrical properties and durability are essential.

• Characteristics: Known for its high melting point and excellent resistance to heat and chemicals. PA66 offers improved strength and dimensional stability compared to PA6.

• Applications: AutomoTorlon 4503 is a 30% glass-reinforced grade that enhances strength and stiffness, making it ideal for structural components subjected to loads. It is commonly used in aerospace and automotive industries, especially for parts that need high strength, rigidity, and resistance to high temperatures.

tive parts, electrical connectors, industrial components.

Torlon 4301 is a composite material filled with PTFE and graphite, offering exceptional wear resistance and low friction. This grade is ideal for moving parts, such as bearings, gears, valve components, where friction and wear are a concern.

Similar to 4301, Torlon 4501 features low friction and outstanding wear resistance, making it perfect for seals, bushings, and bearings in high-performance industrial applications that require durability and low friction.

While these PAI grades have general performance characteristics, their properties can vary depending on several factors, including processing conditions and part design. To ensure the best use of the material, we recommend consulting with the material supplier or materials experts for detailed technical support and advice tailored to your specific needs.

PAI Performance Chart

Polyamide-imide (PAI) is an exceptional high-performance polymer known for its high strength, temperature resistance, and excellent wear properties. Below is a performance chart for the most common grades of PAI used in various applications. This comparison will help you identify the best fit for your project based on mechanical, thermal, and other performance attributes

| Material Grade | Tensile Strength | Max Operating Temp | Hardness (Shore D) | Wear Resistance | Friction Coefficient |

|---|---|---|---|---|---|

| Torlon 4203 | 90 MPa (13,051 psi) | 275°C (527°F) | 85 | Good | Low |

| Torlon 4503 | 140 MPa (20,300 psi) | 280°C (536°F) | 90 | Very Good | Medium |

| Torlon 4301 | 125 MPa (18,200 psi) | 250°C (482°F) | 88 | Excellent | Low |

| Torlon 4501 | 130 MPa (18,900 psi) | 275°C (527°F) | 92 | Very Good | Low |

Please also note that all the numbers provided are approximate values and are given in the Imperial system. The exact properties can vary depending on the manufacturer, grade, and specific application of the material. It’s always advisable to check with the material supplier for the most accurate and current data

PAI Applications

PAI materials like Torlon are widely used in applications that demand extreme durability, resistance to high temperatures, and excellent wear properties. Their high mechanical strength and low friction coefficient make them ideal for aerospace, automotive, and industrial applications. Below are some of the industries and components where PAI excels

Aerospace

Used for components like turbine blades, seals, and aerospace bearings that require high strength and temperature resistance

Automotive

Employed in parts subjected to high loads and high wear, such as gears, valve components, and bushings

Electrical

Perfect for electrical insulators, connectors, and parts requiring resistance to radiation and wear

Industrial

Commonly used in pumps, valves, and bearings where durability and low friction are critical

FAQ

Q: What is PAI material and why is it used in CNC machining?

• PAI, specifically Torlon, is a high-performance thermoplastic known for its strength, heat resistance, and low friction. It is used in CNC machining for parts that need to withstand high loads, harsh environments, and extreme temperatures.

What is the maximum temperature that PAI can withstand?

• Torlon grades like 4203 and 4503 can withstand continuous operating temperatures of up to 280°C (536°F), making it suitable for high-temperature applications in aerospace and automotive industries.

Q: What are the main advantages of using Torlon (PAI) in CNC machining?

• PAI offers excellent wear resistance, high mechanical strength, low friction, and high thermal stability, making it ideal for parts subjected to mechanical stress, temperature extremes, and friction.

Q: Can PAI be used for electrical components?

• Yes, Torlon 4203 and other grades of PAI are ideal for electrical components like insulators and connectors, thanks to their electrical insulation properties and resistance to radiation.

Q: What are some common applications of PAI materials in the industrial sector?

• PAI is widely used in high-performance bearings, gears, seals, valve components, and industrial pumps, especially in applications where high load, low friction, and extreme durability are required.

Q: Is PAI suitable for use in food and medical applications?

• While PAI (Torlon) is chemically inert and non-reactive, it is not commonly used for food-related applications. However, its biocompatibility makes it suitable for medical devices in applications like surgical