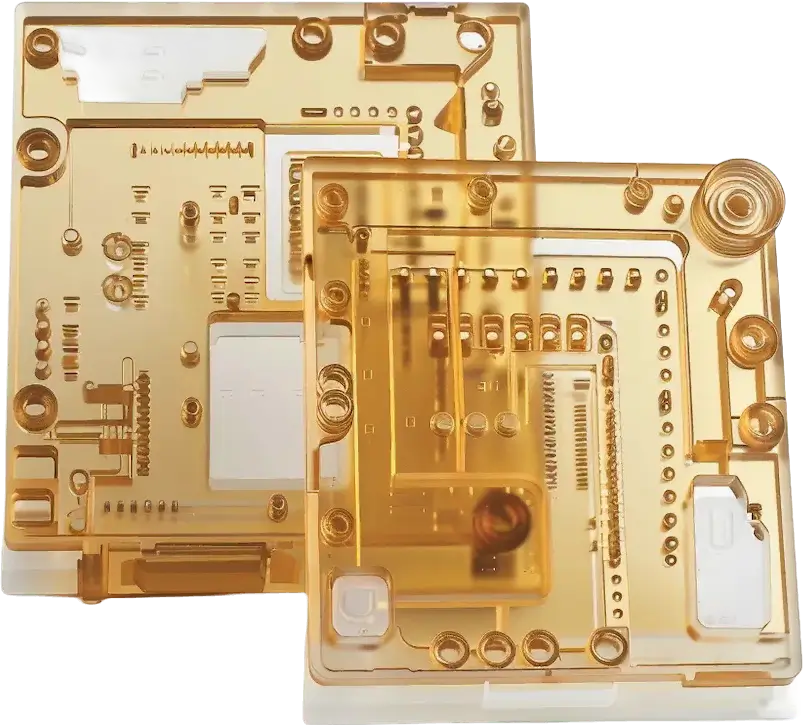

High-Performance PEI CNC Machining Services

We provide precision CNC machining for PEI (Polyetherimide), offering a high-performance material solution for demanding industries like aerospace, automotive, and medical

·Certification materials

·Factory price

·Rapid turnover

·Precision machining

About PEI (Polyetherimide)

PEI (Polyetherimide) is a high-performance thermoplastic that combines excellent strength, dimensional stability, and heat resistance. Known for its outstanding mechanical properties, PEI is ideal for applications requiring long-term performance in high-stress environments. It is commonly used in industries such as aerospace, automotive, and medical, where durability and reliability are crucial

• High-Temperature Resistance

• Exceptional Mechanical Properties

• Chemical Resistance

• Dimensional Stability

• Electrical Insulation

Most common grade of PEI

PEI (Polyetherimide) is available in several grades, each designed to meet specific performance requirements. Below are the common grades of PEI, including their key features and ideal applications

PEI 1000 is a standard grade that offers a good balance between mechanical strength, chemical resistance, and high-temperature stability. It is widely used in aerospace and automotive industries for parts that require exceptional strength and resistance to high temperatures.

PEI 900 provides enhanced dimensional stability and better chemical resistance compared to PEI 1000. It is often used in applications that require precise, durable components, especially in electrical and medical applications.

Glass-filled PEI offers improved mechanical properties, particularly its strength and stiffness. This grade is ideal for parts requiring additional rigidity, making it perfect for structural applications in the automotive, aerospace, and industrial sectors.

PEI 1010 is a specialized grade with superior performance in high-temperature environments, up to 200°C. This grade excels in applications that involve prolonged exposure to extreme conditions.

Compare PEI Performance Characteristics for Different Grades

The table below compares the key properties of various PEI grades,helping you choose the best material for your CNC machining needs

| Property | PEI 1000 | PEI 900 | PEI-GF (Glass-Filled) | PEI 1010 |

|---|---|---|---|---|

| Tensile Strength | 90-110 MPa | 95-115 MPa | 120-140 MPa | 100-120 MPa |

| Flexural Strength | 130-150 MPa | 150-170 MPa | 190-220 MPa | 160-180 MPa |

| Impact Strength | 40-60 kJ/m² | 45-60 kJ/m² | 50-70 kJ/m² | 50-60 kJ/m² |

| Heat Deflection Temperature (HDT) | 170°C (338°F) | 180°C (356°F) | 200°C (392°F) | 200°C (392°F) |

| Density | 1.27 g/cm³ | 1.28 g/cm³ | 1.35 g/cm³ | 1.29 g/cm³ |

| Flammability | UL 94 V-0 | UL 94 V-0 | UL 94 V-0 | UL 94 V-0 |

PEI Applications

PEI is a go-to material for industries that require durable, high-performance parts. Here are some of the primary applications of PEI

FAQ

Q: What is PEI used for in CNC machining?

PEI is used for creating durable and high-performance parts that can withstand extreme temperatures, mechanical stress, and harsh chemicals. It is commonly used in aerospace, automotive, medical, and electrical industries.

Q: Is PEI easy to machine?

Yes, PEI can be machined using standard CNC techniques. It has excellent machinability, allowing it to be used for creating intricate parts and components.

Q: How does PEI compare to other high-performance plastics?

PEI is often compared to PEEK and PTFE, but it offers superior strength, thermal stability, and chemical resistance, making it ideal for a variety of demanding applications.

Q: What are the benefits of glass-filled PEI?

Glass-filled PEI offers enhanced mechanical strength and rigidity, making it suitable for structural applications where additional strength is required.

Q: What industries commonly use PEI?

PEI is commonly used in industries such as aerospace, automotive, medical, electrical, and industrial equipment, where high performance, durability, and dimensional stability are critical.