High-Quality PMMA CNC Machining Services

We offer precision PMMA CNC machining for your projects, ensuring outstanding clarity and durability. Trust our expertise for complex, custom parts that meet your needs

• Fast Turnaround for Prototypes and Production

• High-Precision Machining for Detailed Parts

• Custom Solutions for All Applications

• Expertise in Handling Complex Shapes and Sizes

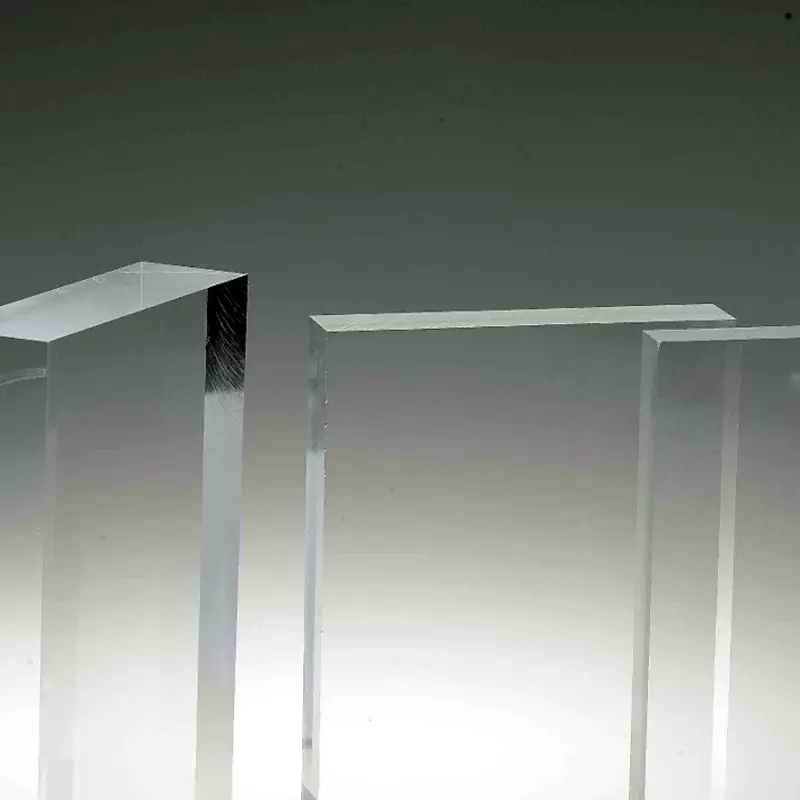

About PMMA

PMMA, also known as acrylic, is a transparent thermoplastic material with high clarity, making it an ideal alternative to glass. It is lightweight, impact-resistant, and can be easily processed through CNC machining to create intricate parts. PMMA offers exceptional transparency and weather resistance, which makes it perfect for applications requiring high visual aesthetics and durability

• Superior Clarity

• Lightweight

• Weather-Resistant

• Impact-Resistant

• Easy to Machine

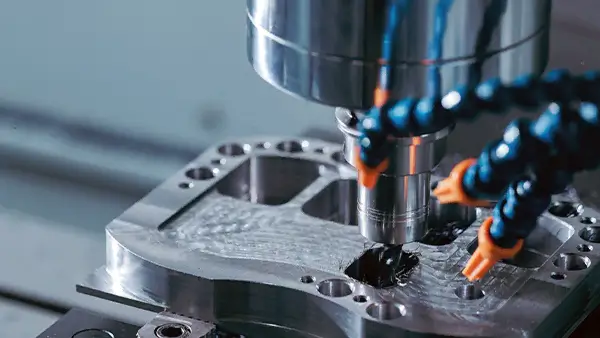

Custom PMMA Machining for Precise, Durable Parts

Our expert team provides high-quality CNC machining services for PMMA, ensuring that your parts meet your specific design and functional requirements. Whether for prototyping or mass production, we deliver results that exceed expectations

Create complex, intricate PMMA parts with precision

Produce cylindrical components and smooth finishes

Polishing & Finishing

Ensure a smooth, clear, and professional finish on every part

Versatile Applications for PMMA CNC Machining

PMMA is widely used across a range of industries for its clarity, strength, and versatility. It is a preferred material for applications that require both aesthetic appeal and durability. Here are some of the industries where PMMA is commonly used:

• Signage and Displays

Ideal for clear signage, lightboxes, and point-of-purchase displays

• Aerospace

Used for cockpit windows, lighting components, and more

• Automotive

Headlights, taillights, and interior parts that require impact resistance and transparency

• Medical Devices

For optical lenses, surgical equipment, and diagnostic tools

• Consumer Electronics

Screens, covers, and panels for electronics requiring transparency and scratch resistance

• Architecture

Window panes, skylights, and architectural elements requiring clarity and weather resistance

FAQ

Q: What is PMMA used for?

PMMA is commonly used for applications requiring transparency, such as signs, displays, automotive lights, and medical devices. It is also used in architecture for windows and skylights.

Q: Is PMMA durable?

Yes, PMMA is highly durable and more resistant to breakage than glass, making it suitable for applications requiring impact resistance.

Q: Can PMMA be easily machined?

Absolutely! PMMA is a versatile material that is easy to machine with CNC, allowing for complex designs and custom shapes.

Q: What are the advantages of PMMA over glass?

PMMA is lighter, more impact-resistant, and easier to machine compared to glass, making it a more durable and cost-effective choice for many applications.

Q: How long does it take to get PMMA parts?

We offer fast turnaround times depending on the complexity and volume of your order. Typically, prototypes can be delivered within 3–5 days.