CNC (Computer Numerical Control) machining has become an industry standard for manufacturing high-precision parts. Whether you’re working on a prototype or mass production, understanding the basics of CNC machining is crucial to making informed decisions. In this guide, we’ll explain what CNC machining is, how it works, the benefits it offers, and the materials you can use. If you’re in need of reliable, high-quality parts, this guide will provide the information you need to get started.

What is CNC Machining?

CNC machining is a manufacturing process in which computer-controlled machines use pre-programmed software to precisely cut and shape materials. This technology ensures high repeatability, precise dimensions, and consistent results for a wide range of parts and components. CNC machining is widely used in various industries, including aerospace, automotive, medical, and electronics, to produce parts with tight tolerances and complex geometries.

In CNC machining, the design is created using CAD (Computer-Aided Design) software, which is then translated into instructions for the machine using CAM (Computer-Aided Manufacturing) software. This process enables manufacturers to produce everything from small batches to large-scale productions with high accuracy.

How Does CNC Machining Work?

Why Choose CNC Machining for Your Projects?

CNC machining offers several advantages, making it a preferred manufacturing solution for businesses:

• High Precision

CNC machines can achieve tolerances as tight as ±0.005 mm, ensuring parts meet exact specifications every time.

• Repeatability and Consistency

Once programmed, CNC machines can consistently replicate parts with uniform accuracy, reducing errors and waste.

• Material Versatility

CNC machining can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics (POM, ABS, Nylon), and composites.

• Efficiency

With CNC machining, you can quickly transition from prototyping to full production, making it ideal for both small runs and large-scale manufacturing.

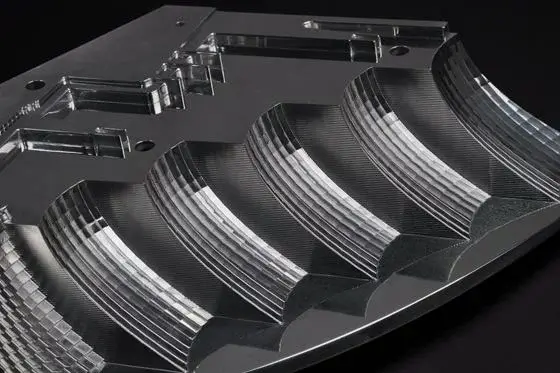

• Complex Geometries

CNC machining is particularly effective for producing complex parts that would be difficult or impossible to achieve using traditional methods.

Common Types of CNC Machines

There are various types of CNC machines, each suited for different tasks:

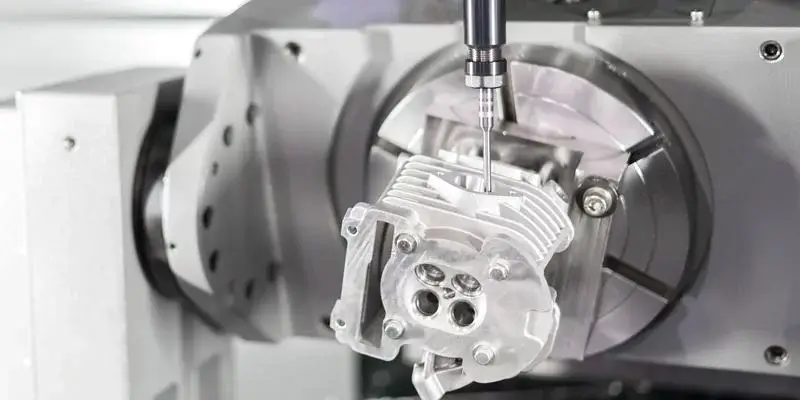

1. CNC Milling

Used for producing parts with complex shapes, CNC mills rotate tools to remove material from a stationary workpiece.

2. CNC Turning

CNC lathes are used to create cylindrical parts by rotating the workpiece and using stationary cutting tools.

3. CNC Laser Cutting

Laser cutting uses a focused laser beam to cut through materials with extreme precision, often used for sheet metals.

4. CNC EDM (Electrical Discharge Machining)

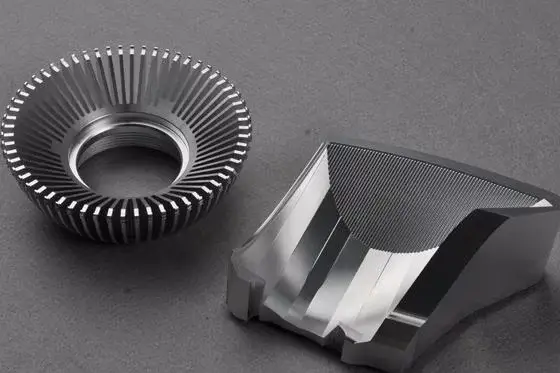

CNC EDM is ideal for precise cuts in hard materials and complex geometries, commonly used in mold-making.

5. CNC Waterjet Cutting

This method uses a high-pressure jet of water mixed with abrasives to cut through materials, ideal for thicker materials and intricate cuts.

Materials for CNC Machining

CNC machining is versatile and can process a variety of materials, including:

• Metals: Aluminum, stainless steel, titanium, copper, and more.

• Plastics: Nylon, POM, ABS, and PTFE.

• Composites: Carbon fiber and fiberglass.

Each material has its own advantages, and selecting the right material is key to ensuring your part performs as required.

Benefits of CNC Machining for Your Project

Whether you’re producing a prototype or a batch of parts, CNC machining provides several key benefits:

• Consistency: CNC machines can consistently produce parts with tight tolerances and intricate designs.

• Speed: Once set up, CNC machines can operate continuously, allowing for faster production times and quicker turnaround.

• Reduced Waste: CNC machines are precise, minimizing material waste and improving cost-efficiency.

• Cost-Effective: While the initial setup might be higher, CNC machining can reduce costs in the long run, especially for large production runs.

CNC Machining Applications

CNC machining is used across many industries for various applications, such as:

• Aerospace: Precision parts for engines, landing gear, and structural components.

• Automotive: Engine components, transmission parts, and custom designs.

• Medical: Custom surgical tools, implants, and diagnostic devices.

• Electronics: Custom enclosures, connectors, and components.

• Industrial Equipment: Gears, shafts, and other machine parts.

CNC machining is a powerful and reliable method for producing high-quality, precise parts for a wide range of industries. Whether you’re designing prototypes, working on small batches, or scaling up to mass production, CNC machining offers the flexibility and efficiency you need to succeed.

By understanding the different types of CNC machines, materials, and processes available, you can make informed decisions that align with your project’s requirements. With the right machining partner, you can ensure top-tier quality, fast turnaround times, and cost-effective solutions.

If you’re ready to take your project to the next level, our expert team is here to guide you every step of the way. Contact us today to discuss how we can help bring your ideas to life with precision CNC machining.