About JXD Machining – Your Trusted Precision Manufacturing Partner

Founded in 2003, Jingxinda (Xiamen) Precision Technology Co., Ltd. (JXD Machining) is a leading precision hardware manufacturer based in Xiamen, China. With a 4,500-square-meter production facility, we specialize in delivering high-precision CNC machining solutions for industries including aerospace, automotive, electronics, optics, medical, and defense.

Over the past two decades, JXD Machining has built a reputation for excellence, serving global clients with custom precision components that meet strict international standards.

Certified for Quality Assurance

We are proudly ISO 9001:2015 and IATF 16949:2016 certified, ensuring that every stage of production adheres to strict quality standards and provides consistent reliability.

Comprehensive Manufacturing Solutions

From CNC machining to sheet metal fabrication, injection molding, casting, and surface treatments, we offer a one-stop service—from initial prototyping to mass production—tailored to meet the diverse needs of our clients.

Expert Team with Cutting-Edge Capabilities

Our team of over 50 skilled engineers, supported by 60+ advanced CNC machines, ensures precise and efficient production. With years of expertise, we deliver components that meet rigorous global quality standards, providing confidence and value to every customer.

Your Reliable Partner in Precision Manufacturing

Trusted by leading companies worldwide, Jingxinda combines technical expertise with an unwavering commitment to quality, making us the ideal partner for your next project.

Certified for Quality Assurance

At JXD Machining, we prioritize precision, consistency, and reliability. We are certified to ISO 9001:2015 and IATF 16949:2016, ensuring that every product meets global industry standards. Our strict quality control processes, including full-scale inspections, guarantee the highest level of accuracy in every order.

Certified for Quality Assurance

At JXD Machining, we prioritize precision, consistency, and reliability. We are certified to ISO 9001:2015 and IATF 16949:2016, ensuring that every product meets global industry standards. Our strict quality control processes, including full-scale inspections, guarantee the highest level of accuracy in every order.

CNC Machining

3-axis, 4-axis, and 5-axis CNC milling & turning

Sheet Metal Fabrication

Cutting, bending, welding, and assembly

Injection Molding

Plastic and metal injection molding solutions

Surface Treatment

Anodizing, plating, powder coating, and more

At JXD Machining, we prioritize precision, consistency, and reliability. We are certified to ISO 9001:2015 and IATF 16949:2016, ensuring that every product meets global industry standards. Our strict quality control processes, including full-scale inspections, guarantee the highest level of accuracy in every order.

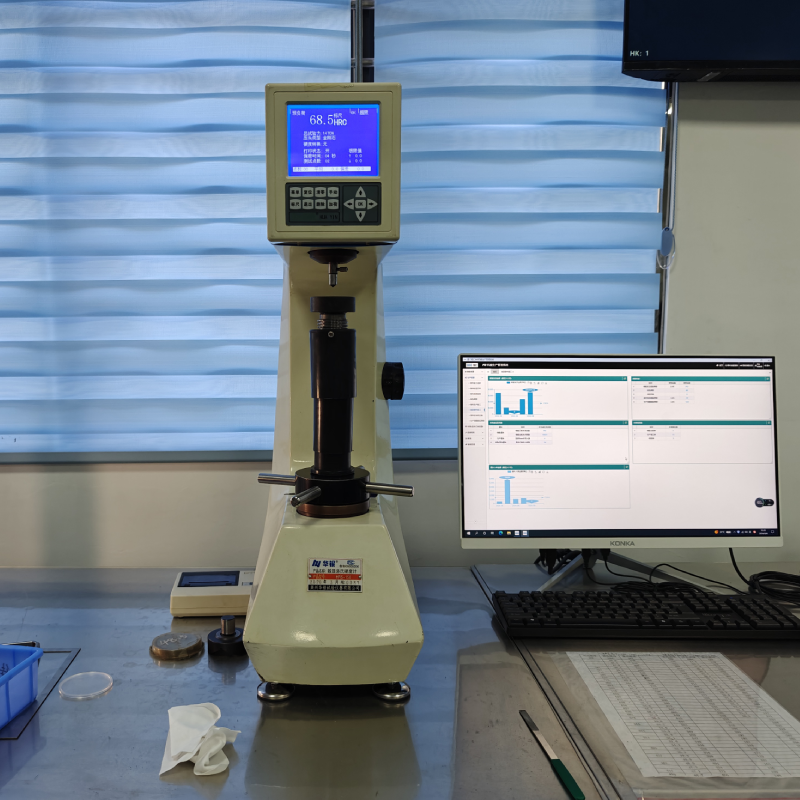

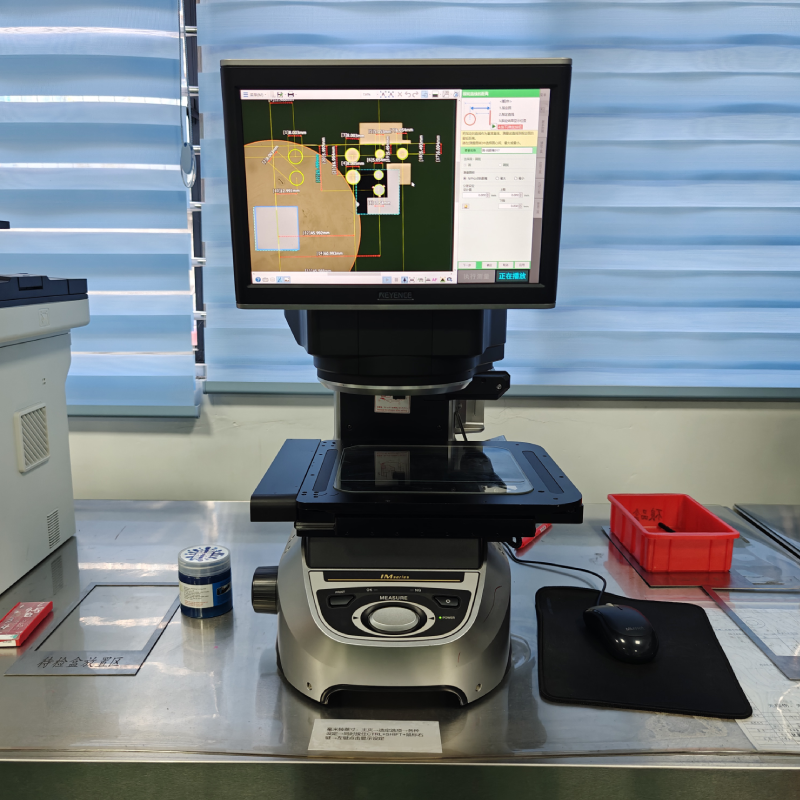

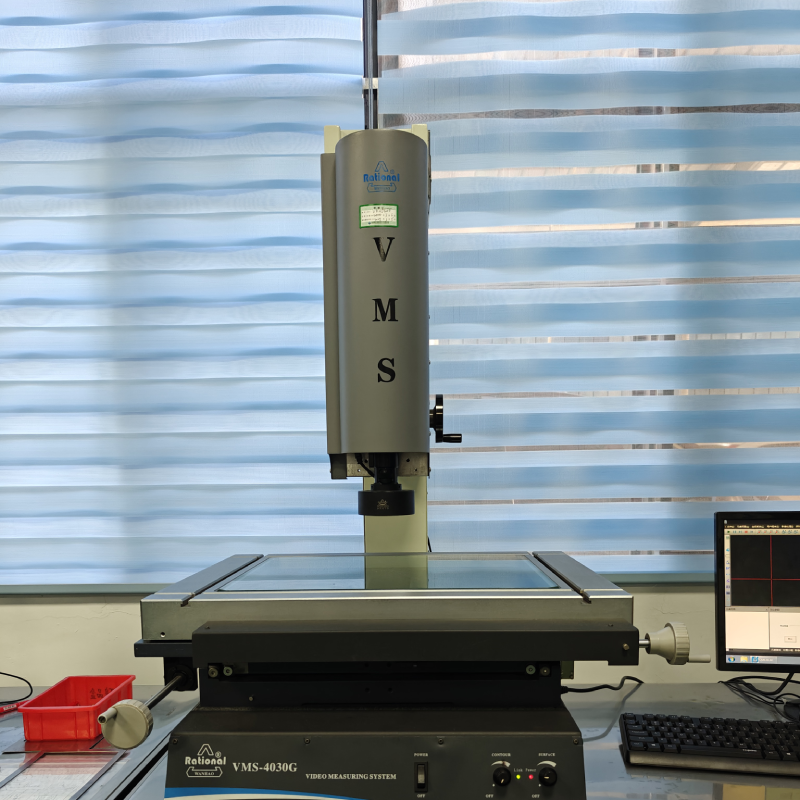

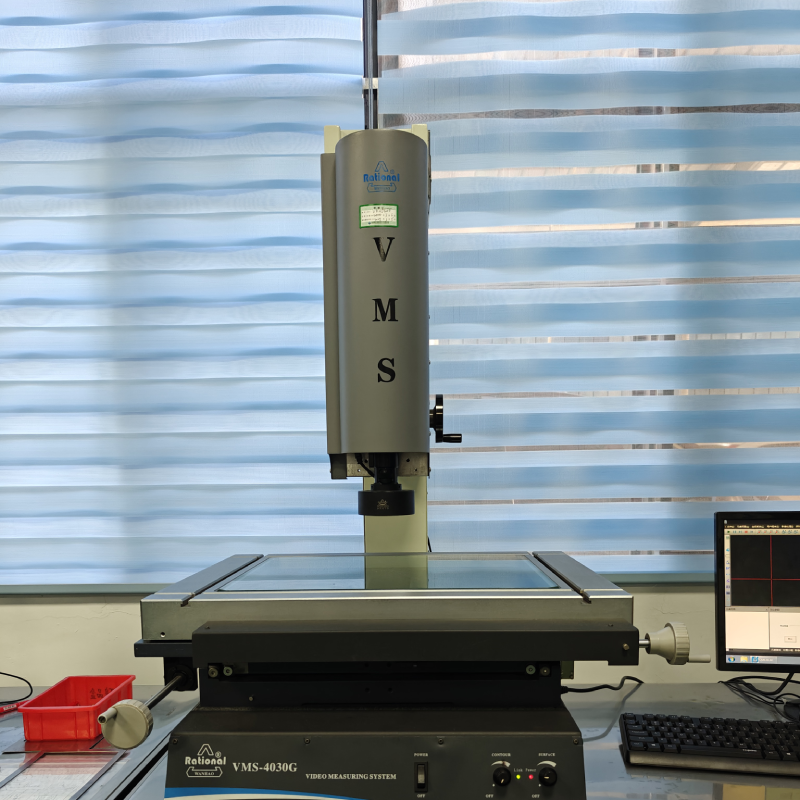

Our Workshop & Equipment

At JXD Precision Technology, we invest in cutting-edge manufacturing equipment to ensure high precision, efficiency, and scalability. Our advanced CNC machines, automated production lines, and rigorous quality control systems allow us to deliver custom precision components with tight tolerances (±0.005mm) and exceptional consistency.

CNC machining inspection CMMS

CNC machining inspection VMS

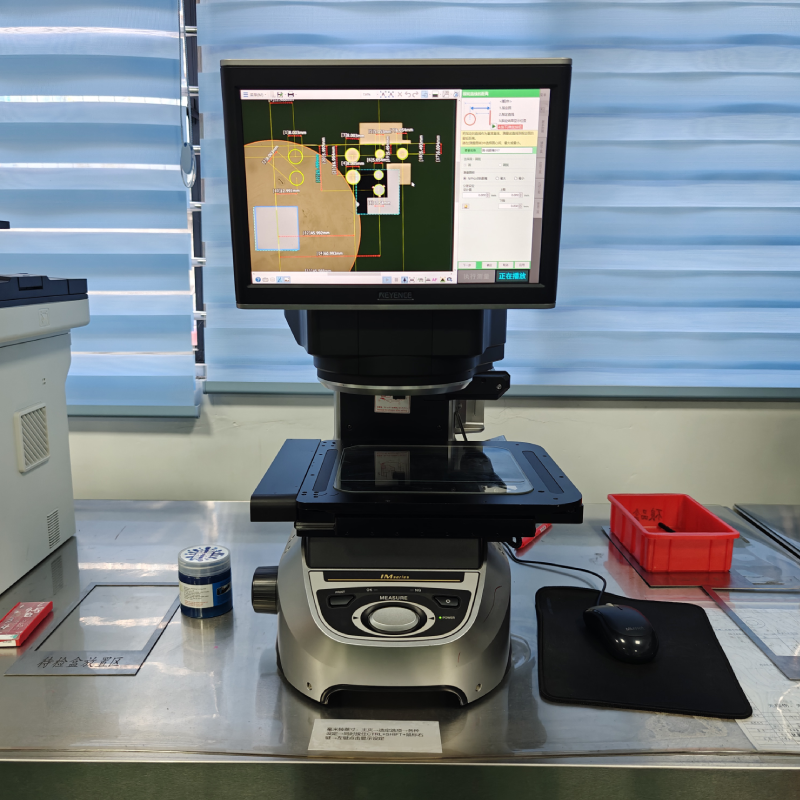

CNC machining inspection IM

CNC machining inspection HRS

CNC machining inspection high

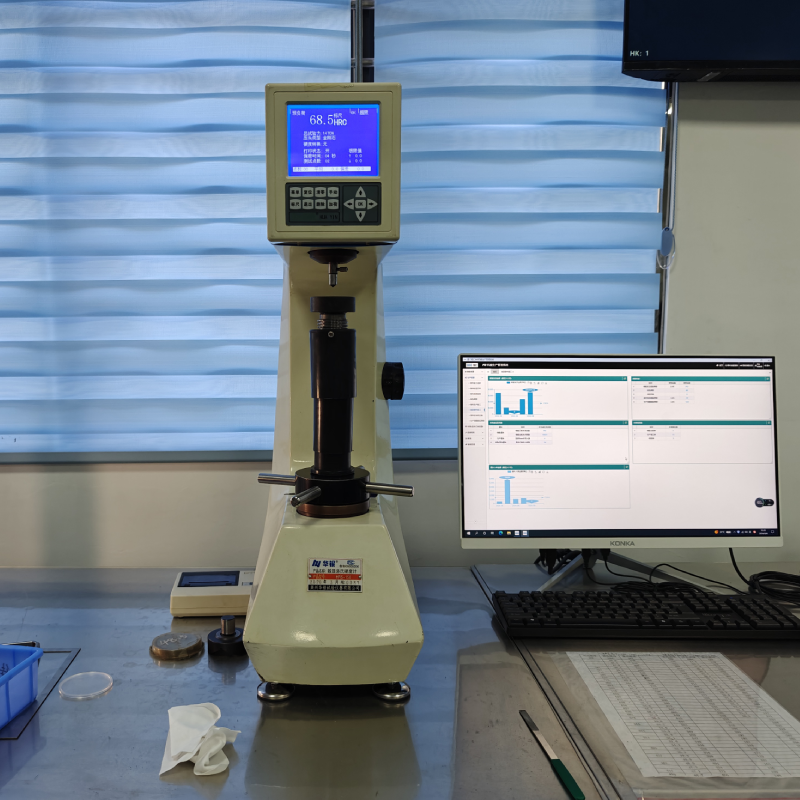

CNC machining inspection hardness

CNC machining inspection CMMS

FAQ

Q: What industries do you serve?

A: We cater to a wide range of industries, including aerospace, automotive, electronics, medical devices, and more.

Q: Can you handle small batch production?

A: Yes, we specialize in both small-batch prototypes and large-scale production to meet diverse customer needs.

Q: What materials can you work with?

A: We work with metals like aluminum, stainless steel, and titanium, as well as plastics and ceramics for specialized applications.

Q: How do you ensure quality control?

A: We use advanced inspection equipment, such as CMMs, and follow rigorous testing protocols to ensure every part meets the required standards.

Q: What is the typical lead time for orders?

A: Lead times depend on the complexity and volume of the order, but we offer rapid prototyping and efficient production schedules.