Wire EDM Machining Services

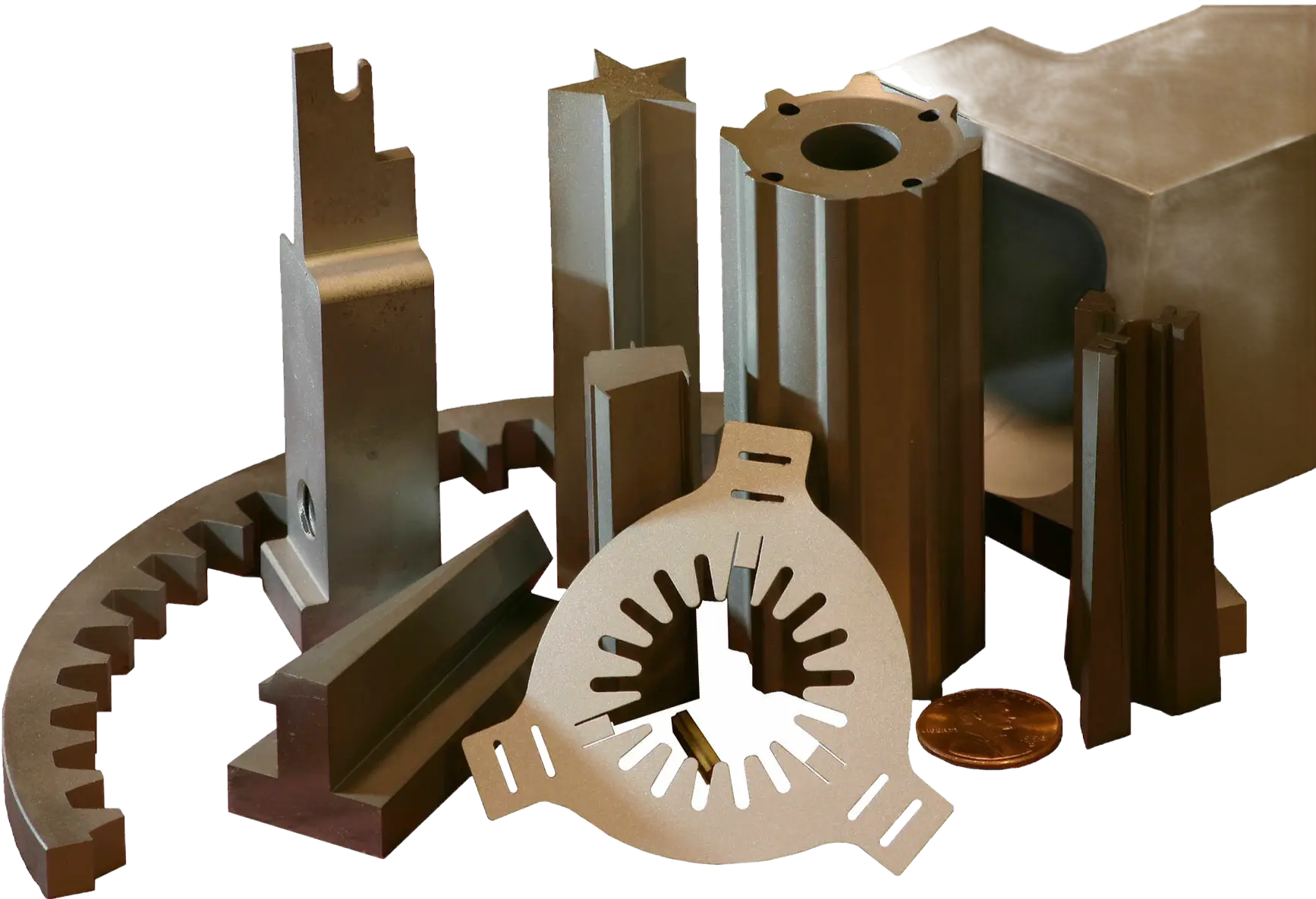

Our precision wire - cutting service flawlessly replicates complex geometries, meeting the most stringent standards. Certified to ISO 9001, ISO 13485, ISO 14001, and IATF 16949

•Tolerance: Up to ±0.001mm

•Material Range: Aluminum, Steel, Titanium, and more

•Fast Turnaround: Samples in 3 days, bulk production supported

What is Wire EDM?

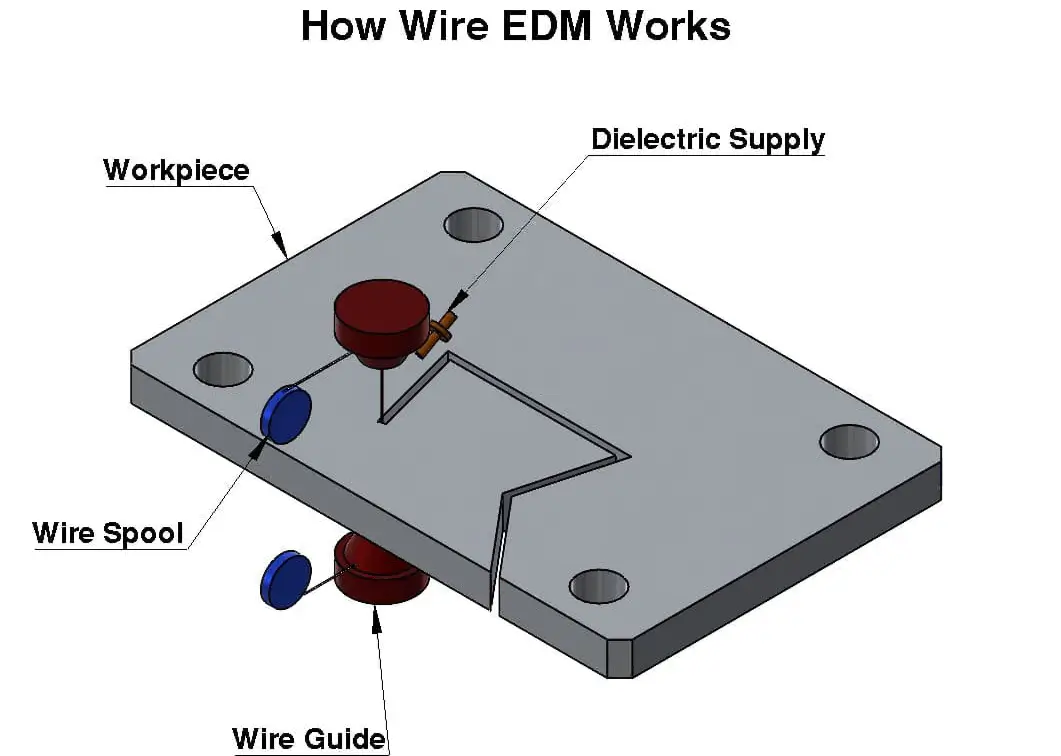

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, continuously moving wire as an electrode to cut electrically conductive materials. This process allows for the creation of complex shapes and intricate details with unmatched precision.

•Non-contact process: Ensures no mechanical stress on parts.

•Precision: Ideal for components with tight tolerances and fine features.

•Material flexibility: Suitable for metals, alloys, and superalloys.

Wire EDM

——————

Wire EDM is the go-to solution for cutting intricate and complex shapes with unmatched precision. This process utilizes a thin wire as an electrode to create detailed contours in electrically conductive materials, all without introducing mechanical stress to the workpiece. From aerospace turbine blades to delicate components in the electronics industry, Wire EDM excels in creating parts with extreme accuracy and fine finishes.

Whether you’re prototyping or producing high volumes, Wire EDM ensures consistency across every piece, delivering parts that meet even the most stringent tolerances. It’s particularly ideal for projects requiring clean edges and complex geometries that other methods simply cannot achieve.

Sinker EDM

——————

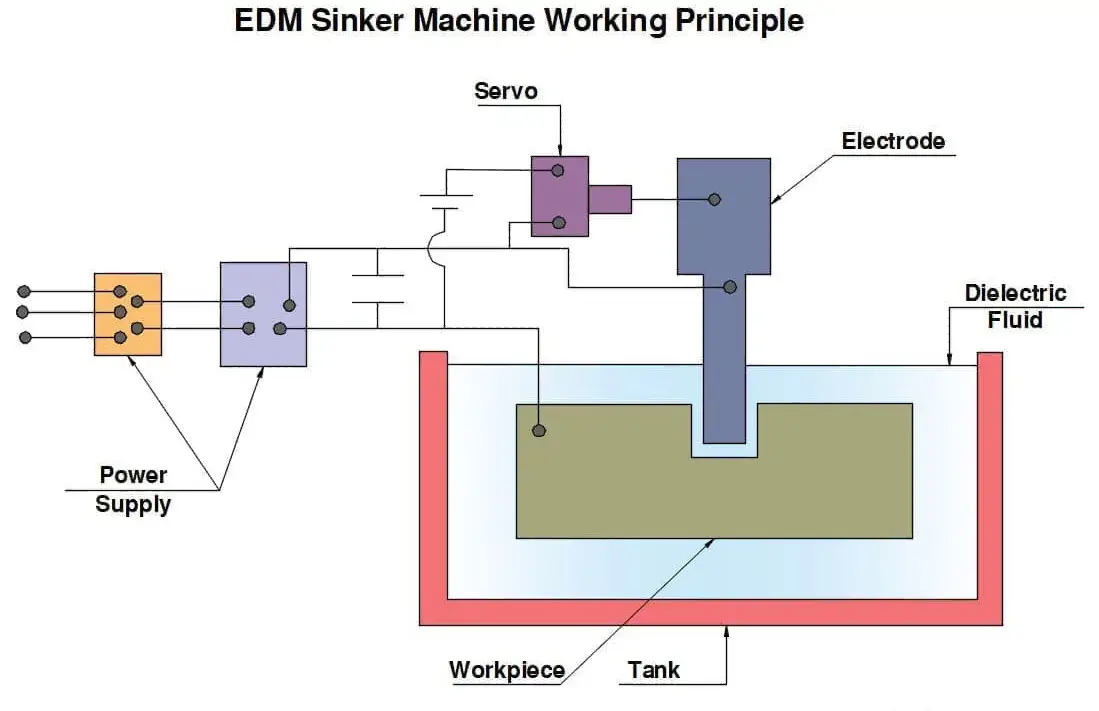

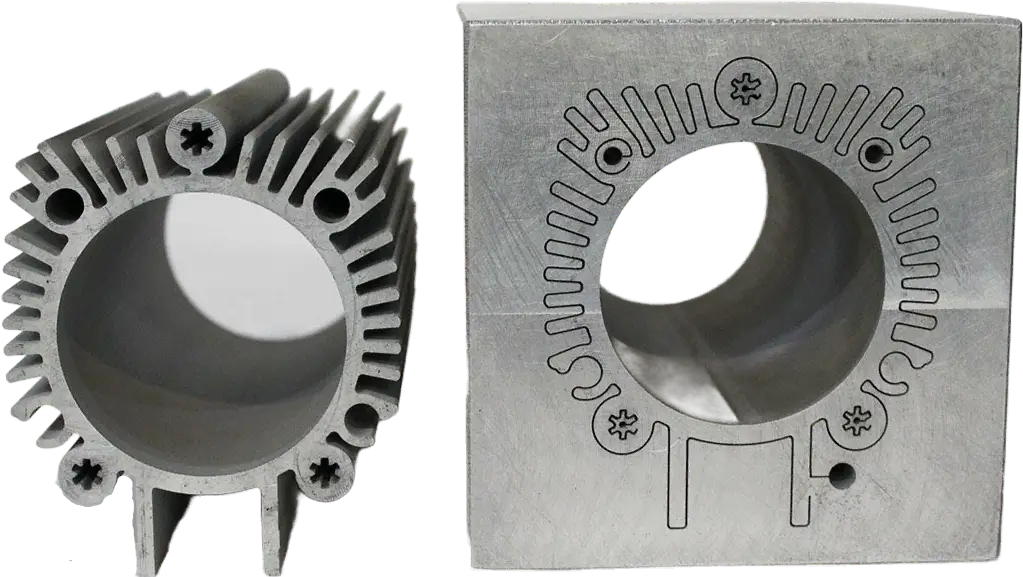

Sinker EDM is the answer when you need to create intricate cavities, deep slots, or blind holes in hard materials. This method uses a custom-shaped electrode to “sink” into the workpiece, making it perfect for producing molds, dies, and parts with non-standard geometries.

Industries like automotive, medical, and aerospace often rely on Sinker EDM for parts that demand durability and precise detail. Whether it’s a complex injection mold or a custom die with unique specifications, this process ensures accuracy without compromising material integrity.

Sinker EDM shines in situations where traditional machining methods fall short, offering a reliable way to achieve detailed internal features and smooth finishes in tough materials.

Hole Drilling EDM

——————

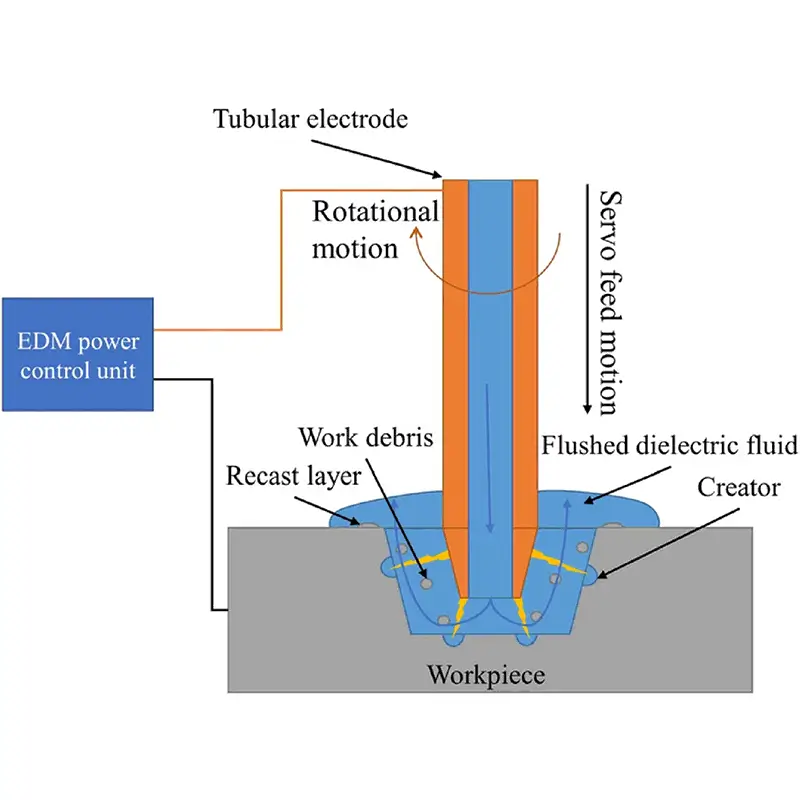

Hole Drilling EDM specializes in creating small, deep, or angled holes in challenging materials like hardened steel or exotic alloys. This process is widely used in industries such as aerospace and energy, where precision cooling holes or oil passages are critical.

Unlike traditional drilling methods, Hole Drilling EDM can penetrate tough materials with ease, delivering clean, burr-free results. It’s a game-changer for parts that require intricate internal pathways or tiny apertures that standard methods cannot achieve.

Wire EDM Applications

Aerospace

• Turbine blades

• Structural components

• Precision connectors

Electronics

• Heat sinks

• Micro parts

• Semiconductor molds

Why Choose Wire EDM for Your Next Project?

————————————

1. Unmatched Precision: Achieve tolerances as tight as ±0.001mm.

2. Stress-Free Processing: Non-contact cutting ensures no deformation.

3. Material Versatility: Handles a wide range of conductive materials, including hard-to-machine metals.

4. Complex Geometry: Capable of producing intricate shapes and fine details.

5. Eco-Friendly Process: Minimal material waste, energy-efficient operations.

Why Choose Our Wire EDM Services?

Wire EDM Services FAQs

1. What are the typical tolerances you can achieve with Wire EDM?

Our Wire EDM machines can achieve tolerances as tight as ±0.002 mm, ensuring precision for even the most intricate designs. For specific requirements, let us know, and we’ll tailor the process to meet your needs.

2. What is the maximum thickness of materials you can cut?

We can process materials up to 500 mm in thickness, depending on the complexity of the design. Please share your part specifications for a detailed evaluation.

3.Do you offer prototyping services?

Yes, we offer rapid prototyping for Wire EDM parts, helping you test designs and functionality before moving to full-scale production. This ensures you receive accurate, high-quality components every time.

4.Do you provide surface treatments after Wire EDM machining?

Yes, we offer a variety of post-processing options, including polishing, anodizing, plating, and more. This ensures your parts meet functional and aesthetic requirements.

5.What information do I need to provide for a quote?

To provide an accurate quote, we need the following details:

• Technical drawings or 3D files (e.g., CAD models)

• Material specifications

• Tolerance requirements

• Quantity

• Any additional processing or finish